POWER IN LINE

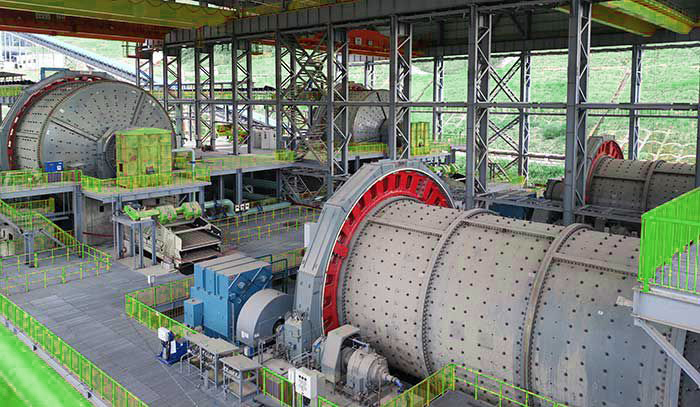

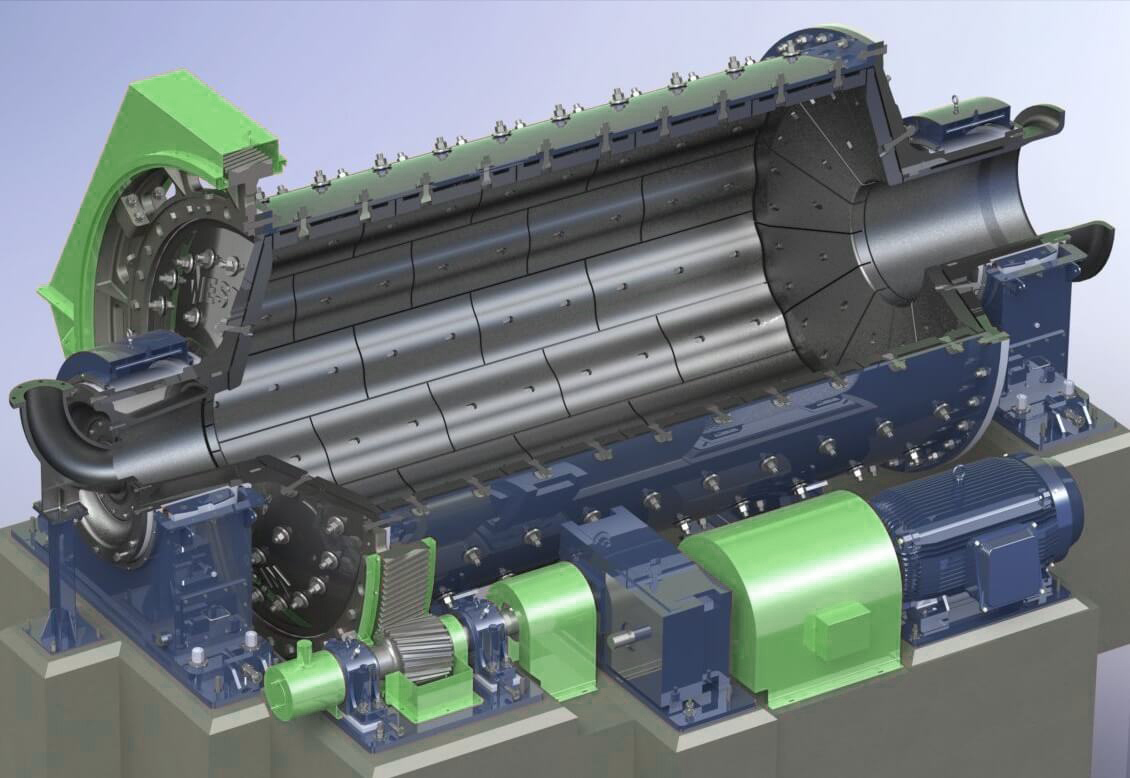

The rod mill is a specialized grinding machine used in mineral processing. Operating with high-carbon steel rods, it efficiently breaks down materials using a cascading motion. Compared to ball mills, its parallel rod alignment ensures controlled grinding, preventing fine particles from agglomerating and producing a more uniform final product.

Designed for feed sizes up to 25 mm, the rod mill is not suitable for extremely hard materials. Over time, rods wear out and should be replaced periodically, offering a cost-effective alternative to balls. It is particularly effective for grinding sticky materials, as the heavier rods help prevent clumping, ensuring a smoother and more efficient process.

| Model | Drum Diameter (mm) | Drum Length (mm) | Capacity (tons/hour) | Rotating Speed (RPM) | Motor Power (kW) | Approx. Weight (kg) |

|---|---|---|---|---|---|---|

| RM-600 | 600 | 900 | 0.3 – 0.7 | 36 | 5.5 | 2200 |

| RM-900 | 900 | 1800 | 0.7 – 1.5 | 30 | 11 | 4200 |

| RM-1200 | 1200 | 2400 | 1.5 – 3.5 | 26 | 22 | 8000 |

| RM-1500 | 1500 | 3000 | 3 – 6 | 23 | 37 | 13000 |

| RM-1800 | 1800 | 3600 | 5 – 10 | 21 | 55 | 19000 |

| RM-2000 | 2000 | 4000 | 7 – 14 | 19 | 75 | 26000 |

| RM-2200 | 2200 | 4500 | 9 – 18 | 17 | 90 | 34000 |

| RM-2400 | 2400 | 5000 | 11 – 22 | 15 | 110 | 42000 |

| RM-2600 | 2600 | 5200 | 13 – 26 | 14 | 132 | 52000 |

| RM-2800 | 2800 | 5600 | 15 – 30 | 13 | 160 | 62000 |

| RM-3000 | 3000 | 6000 | 18 – 36 | 12 | 185 | 73000 |

| RM-3200 | 3200 | 6400 | 20 – 40 | 11 | 220 | 85000 |

| RM-3400 | 3400 | 6800 | 23 – 46 | 10 | 250 | 95000 |

| RM-3600 | 3600 | 7200 | 26 – 52 | 9 | 280 | 105000 |

| RM-3800 | 3800 | 7600 | 30 – 60 | 8 | 315 | 115000 |

NOTE: Our company manufactures systems in a wide range of capacities, from laboratory scale to industrial scale. To receive a price quote for your desired capacity, please send an email to

info@proses-makina.com