SETTLING FOR FILTRATION

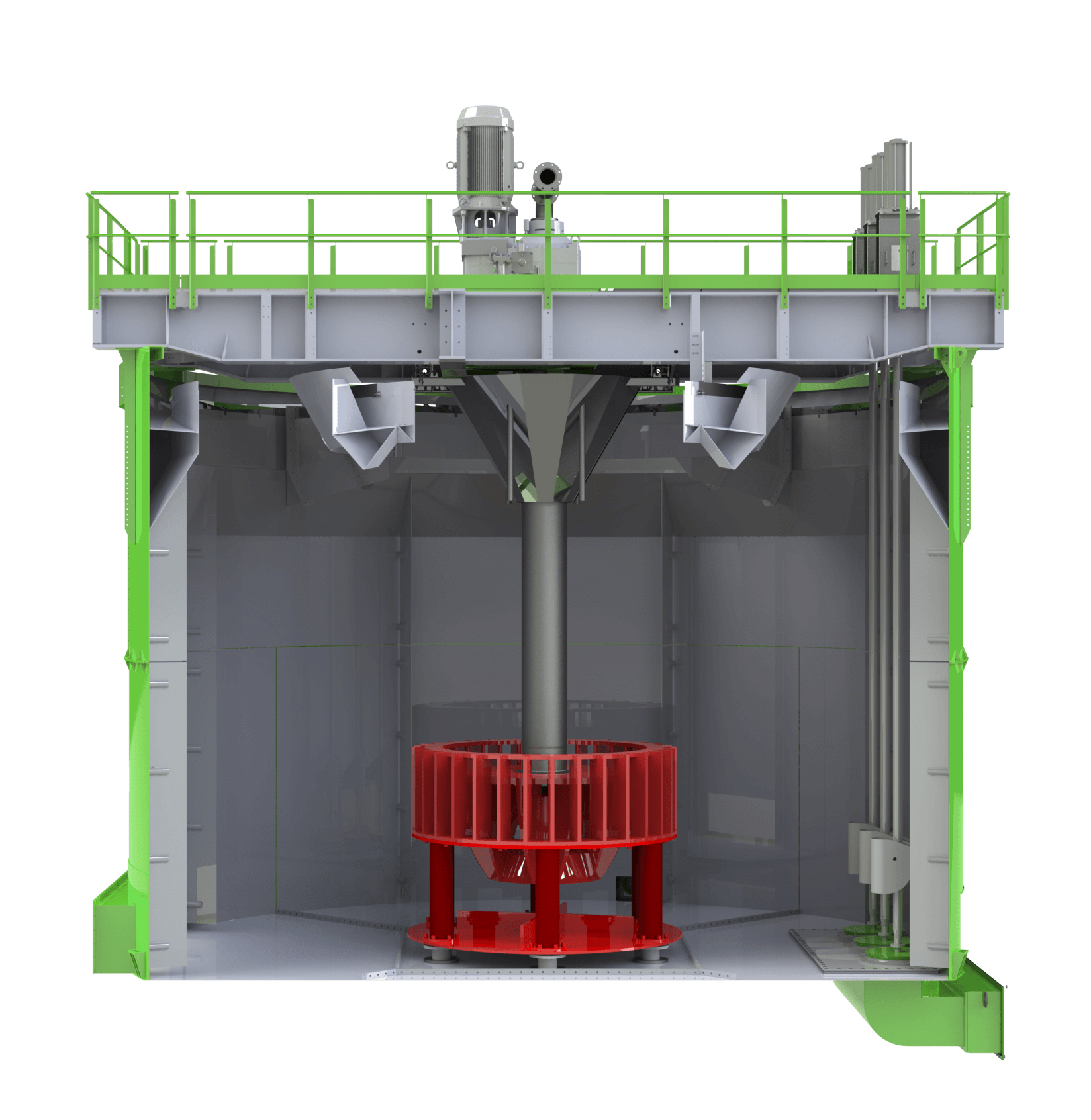

Our industrial thickeners are engineered to handle a wide range of slurries generated during ore beneficiation, leaching, flotation, and tailings management. Designed for robustness and process reliability, our thickening systems provide high underflow density and excellent clarity of overflow water, improving the efficiency of downstream filtration and dewatering equipment such as filter presses, vacuum filters, or centrifuges.

We offer both conventional thickeners and high-rate thickeners, depending on the process requirements: Conventional thickeners are suitable for lower throughput operations or when a larger tank footprint is acceptable. High-rate thickeners, equipped with optimized feedwell designs and flocculation systems, achieve faster settling rates and require significantly less floor space, making them ideal for modern, compact plants.

Key features of our thickeners include:

Whether your application involves primary metal production, precious metal recovery, or mine tailings treatment, our thickeners are tailored to integrate seamlessly into your process and optimize overall plant performance.

| Model | Tank Diameter (m) | Tank Depth (m) | Capacity (m³/h) | Rake Torque (kNm) | Drive Power (kW) | Approx. Weight (kg) |

|---|---|---|---|---|---|---|

| TK-5 | 5 | 2 | 15 – 30 | 5 | 1.5 | 8000 |

| TK-7 | 7 | 2.5 | 25 – 50 | 7 | 2.2 | 12000 |

| TK-9 | 9 | 2.8 | 45 – 80 | 10 | 3 | 18000 |

| TK-12 | 12 | 3 | 70 – 120 | 15 | 4 | 25000 |

| TK-15 | 15 | 3.5 | 120 – 200 | 20 | 5.5 | 32000 |

| TK-18 | 18 | 4 | 180 – 300 | 25 | 7.5 | 42000 |

| TK-20 | 20 | 4.5 | 240 – 400 | 32 | 11 | 55000 |

| TK-22 | 22 | 5 | 300 – 500 | 38 | 15 | 65000 |

| TK-25 | 25 | 5.5 | 400 – 650 | 45 | 18.5 | 78000 |

| TK-28 | 28 | 6 | 500 – 800 | 55 | 22 | 90000 |

| TK-30 | 30 | 6.5 | 600 – 900 | 65 | 30 | 105000 |

| TK-32 | 32 | 7 | 700 – 1050 | 75 | 37 | 120000 |

| TK-35 | 35 | 7.5 | 800 – 1200 | 90 | 45 | 140000 |

| TK-38 | 38 | 8 | 900 – 1350 | 110 | 55 | 160000 |

| TK-40 | 40 | 8.5 | 1000 – 1500 | 125 | 75 | 180000 |

NOTE: Our company manufactures systems in a wide range of capacities, from laboratory scale to industrial scale. To receive a price quote for your desired capacity, please send an email to

info@proses-makina.com