A grizzly feeder is designed to seperate fines from larger rock pieces. It consist of the series bar sor tines mounted on a vibrating platform. Materials are...

Seperate and Transfer

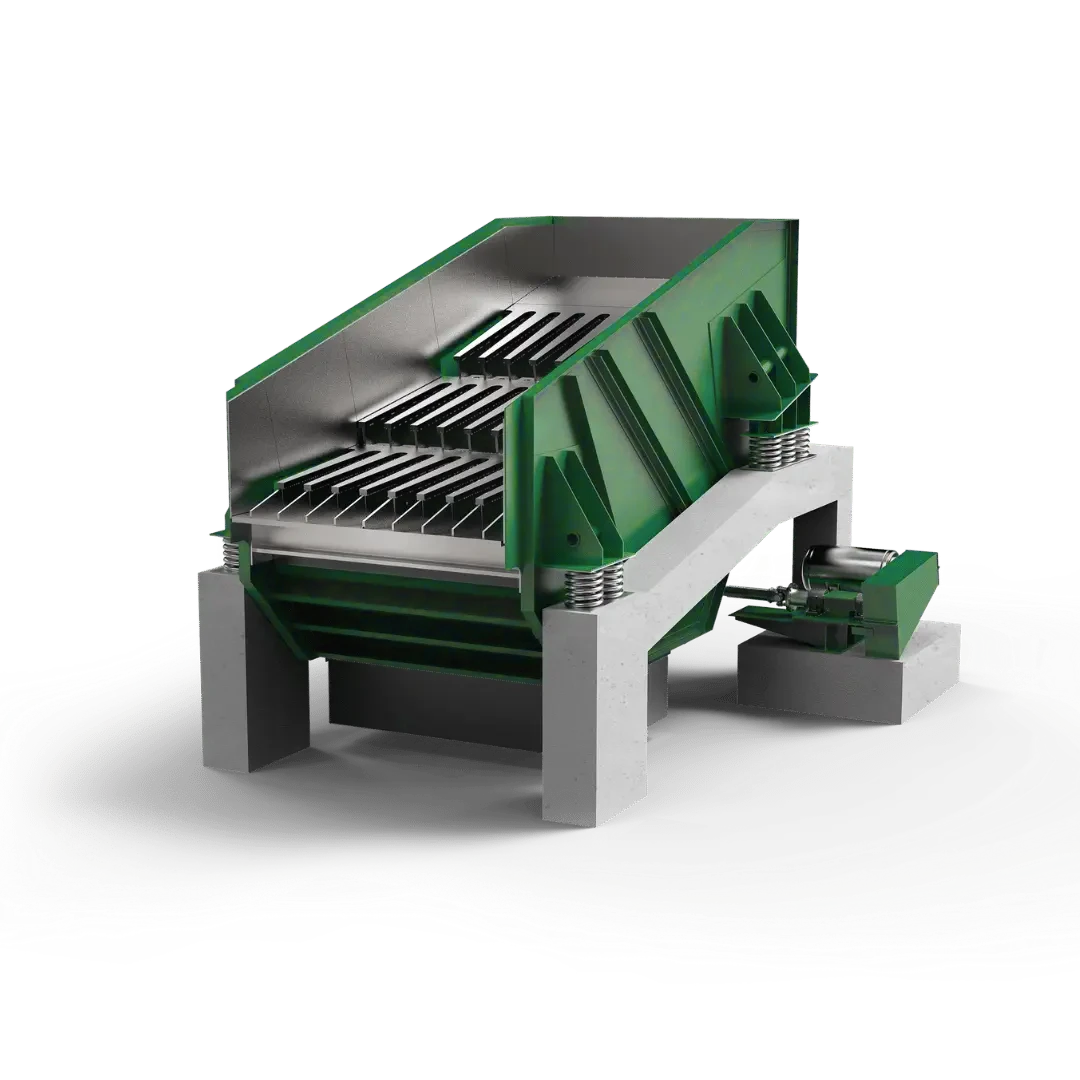

A grizzly feeder is designed to seperate fines from larger rock pieces. It consist of the series bar sor tines mounted on a vibrating platform. Materials are naturally sorted by their size as they pass over the the grizzly lines. The finer fractions drop immediately into the crushing chamber while oversized pieces are recirculated for secondary processing.

The modular design allows for quick adjustments, minimizing setup time while providing the precise control needed to handle different ore sizes and maintain consistent throughput. By adressing the core issues of traditional systems, our grizzly feeder that material handling is both efficient and scalable, paying the way for increased mining productivity.

| Model | Capacity (tons/hour) | Deck Width (mm) | Deck Length (mm) | Motor Power (kW) | Vibration Frequency (RPM) | Max Feed Size (mm) | Approx. Weight (kg) |

|---|---|---|---|---|---|---|---|

| GF-300 | 50 – 100 | 800 | 3000 | 5.5 | 900 | 400 | 2500 |

| GF-400 | 100 – 200 | 1000 | 3500 | 7.5 | 900 | 500 | 3000 |

| GF-500 | 150 – 250 | 1100 | 4000 | 9.0 | 850 | 600 | 3500 |

| GF-600 | 200 – 300 | 1200 | 4500 | 11 | 850 | 700 | 4000 |

| GF-700 | 250 – 400 | 1300 | 5000 | 15 | 800 | 800 | 4500 |

| GF-800 | 300 – 500 | 1400 | 5500 | 18.5 | 800 | 900 | 5000 |

| GF-900 | 400 – 600 | 1500 | 6000 | 22 | 750 | 900 | 5500 |

| GF-1000 | 500 – 700 | 1600 | 6500 | 30 | 750 | 1000 | 6000 |

| GF-1100 | 600 – 800 | 1700 | 7000 | 37 | 700 | 1000 | 6500 |

| GF-1200 | 700 – 900 | 1800 | 7500 | 45 | 700 | 1000 | 7000 |

| GF-1300 | 800 – 1000 | 2000 | 8000 | 55 | 700 | 1000 | 7500 |

| GF-1400 | 900 – 1100 | 2200 | 8500 | 75 | 700 | 1000 | 8000 |

| GF-1500 | 1000 – 1200 | 2400 | 9000 | 90 | 700 | 1000 | 8500 |

| GF-1600 | 1100 – 1300 | 2600 | 9500 | 110 | 700 | 1000 | 9000 |

| GF-1800 | 1200 – 1400 | 2800 | 10000 | 132 | 700 | 1000 | 9500 |

NOTE: Our company manufactures systems in a wide range of capacities, from laboratory scale to industrial scale. To receive a price quote for your desired capacity, please send an email to

info@proses-makina.com