STRIKE ON HARDNESS

Hammer mills are highly effective for processing catalytic converters due to their ability to rapidly pulverize the brittle ceramic monolith structure found inside most converters. These monoliths, typically made from alumina-based ceramics with a honeycomb design, are hard yet fragile, making them ideal candidates for impact-based crushing. Hammer mills utilize high-speed rotating hammers that shatter the substrate into a fine, homogeneous powder. This fine milling significantly enhances the liberation of platinum group metals (PGMs), such as platinum, palladium, and rhodium, from the ceramic matrix, enabling higher recovery yields in downstream processes.

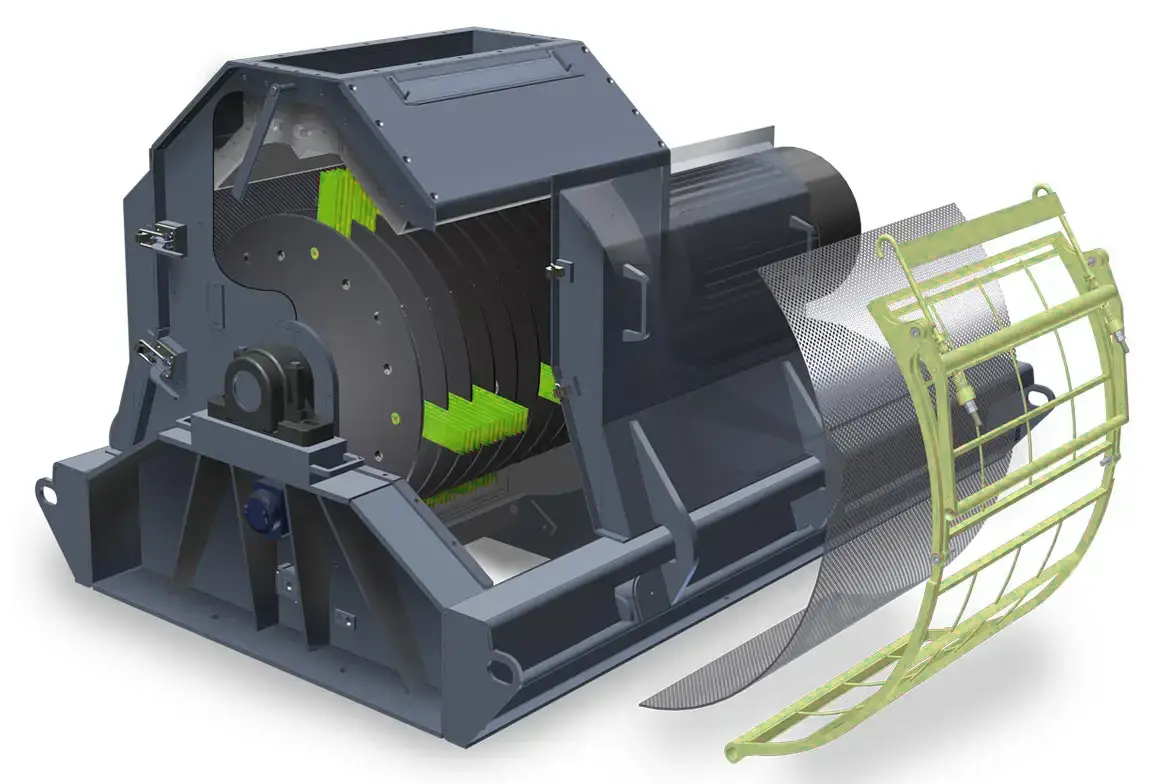

They operate by rapidly rotating hammers that impact materials, causing them to shatter. The material then strikes the inner breaker plate, further reducing its size. High-speed hammer mills with small-diameter rotors are preferred for fine grinding, while tip speed influences the particle trajectory and grinding efficiency. The screen opening size determines particle size and energy consumption, with smaller openings requiring more energy. Larger particles are retained for further grinding, which increases size reduction efficiency but also leads to wear on the mill’s interior.

Different breakage patterns are observed between hard and soft materials; the formation of finer particles is associated with increased wear. The arrangement of the grinders affects the breakage mechanism, which in turn alters the particle distribution. The mill performance can be optimized in different ways depending on rotor speed and feed rate.

Hammer mills offer faster processing times, lower energy consumption, and more consistent particle size distribution, which is critical for accurate sampling and valuation of precious metal content. They can operate continuously with high throughput (up to 1 ton per hour), making them well-suited for industrial-scale applications. They are commonly integrated with dust collection systems (cyclones and baghouse filters) to prevent the loss of valuable PGM-containing dust and to meet occupational health and safety standards. With relatively low maintenance requirements and adaptability to both ceramic and metallic converters, hammer mills are a cost-effective and essential component of any modern catalytic converter recycling.