The vibrating feeder incorporates key elements that enhance its performance under demanding operating conditions. The unit features a motor-driven vibrator m...

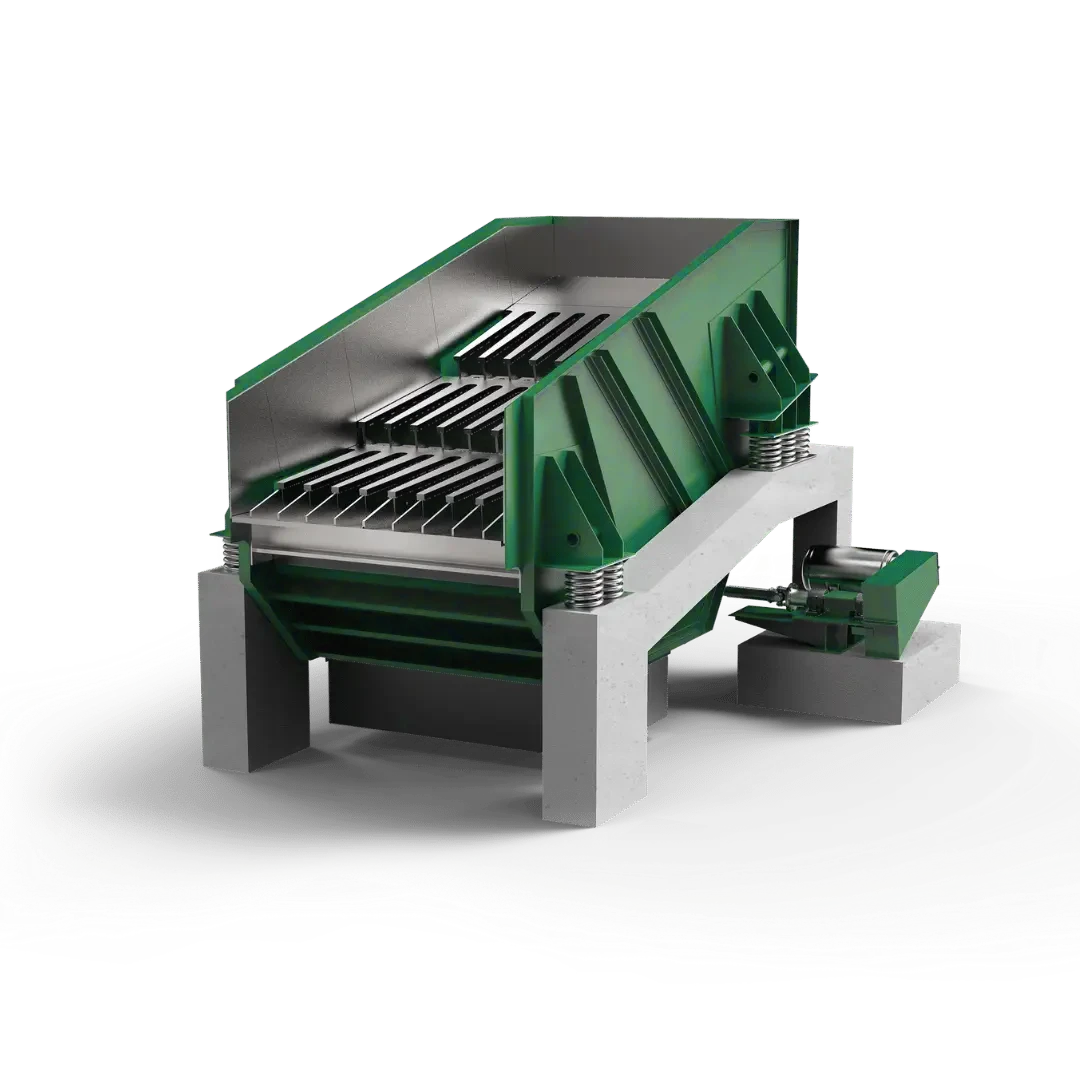

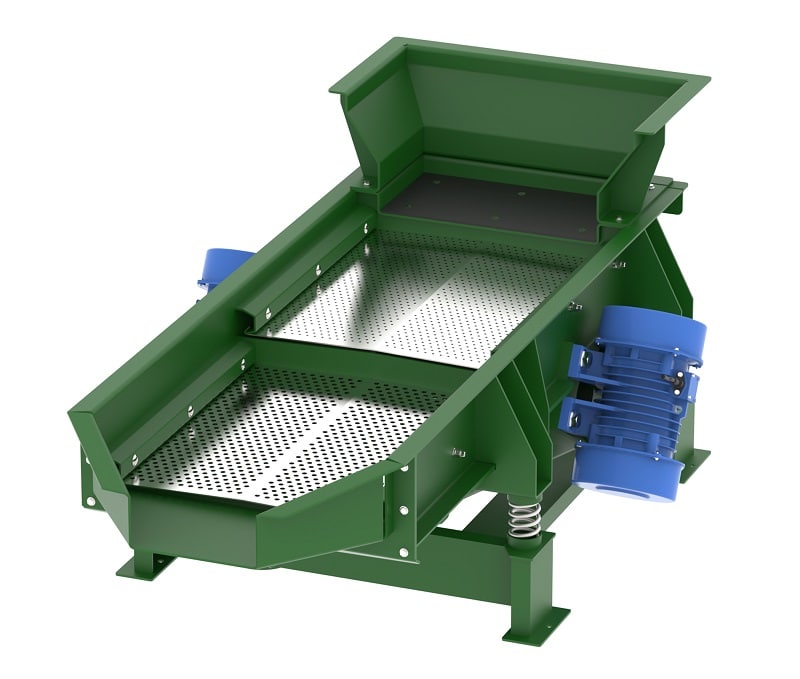

The vibrating feeder incorporates key elements that enhance its performance under demanding operating conditions. The unit features a motor-driven vibrator mechanism that imparts controlled oscillations to a trough, ensuring uniform material flow.

Critical components such as resilient support frames, damping devices, and adjustable feeding rates provide our customers with precise control over the feeding process. Industry standard materials and precision engineering allow the equipment to withstand extreme environmental conditions, minimizing downtime and maintenance costs. The design supports high-volume bulk material processing, making it an ideal choice for large-scale manufacturing operations.

| Model | Capacity (tons/hour) | Trough Width (mm) | Trough Length (mm) | Motor Power (kW) | Vibration Frequency (RPM) | Max Feed Size (mm) | Approx. Weight (kg) |

|---|---|---|---|---|---|---|---|

| VF-300 | 30 – 60 | 400 | 1800 | 2 x 1.1 | 1500 | 200 | 1000 |

| VF-400 | 50 – 100 | 500 | 2000 | 2 x 1.5 | 1500 | 300 | 1200 |

| VF-500 | 75 – 150 | 600 | 2500 | 2 x 2.2 | 1400 | 350 | 1500 |

| VF-600 | 100 – 200 | 700 | 2800 | 2 x 3.0 | 1300 | 400 | 1800 |

| VF-700 | 150 – 300 | 800 | 3000 | 2 x 3.7 | 1200 | 500 | 2100 |

| VF-800 | 200 – 400 | 900 | 3200 | 2 x 4.0 | 1150 | 600 | 2500 |

| VF-900 | 250 – 500 | 1000 | 3500 | 2 x 5.5 | 1100 | 700 | 2800 |

| VF-1000 | 300 – 600 | 1100 | 3800 | 2 x 5.5 | 1000 | 800 | 3200 |

| VF-1100 | 400 – 700 | 1200 | 4000 | 2 x 7.5 | 950 | 900 | 3500 |

| VF-1200 | 500 – 800 | 1300 | 4500 | 2 x 7.5 | 900 | 900 | 4000 |

| VF-1300 | 600 – 900 | 1400 | 4800 | 2 x 9.0 | 900 | 1000 | 4500 |

| VF-1400 | 700 – 1000 | 1500 | 5000 | 2 x 11 | 850 | 1100 | 5000 |

| VF-1500 | 800 – 1200 | 1600 | 5500 | 2 x 11 | 850 | 1200 | 5500 |

| VF-1600 | 1000 – 1400 | 1700 | 6000 | 2 x 15 | 800 | 1200 | 6000 |

| VF-1800 | 1200 – 1600 | 1800 | 6500 | 2 x 18.5 | 750 | 1200 | 7000 |

NOTE: Our company manufactures systems in a wide range of capacities, from laboratory scale to industrial scale. To receive a price quote for your desired capacity, please send an email to

info@proses-makina.com