The screw feeder efficiently meters bulk solid materials ensuring performance of the plant. It consists of a helical screw that rotates inside a confinement ...

Efficiency in Motion

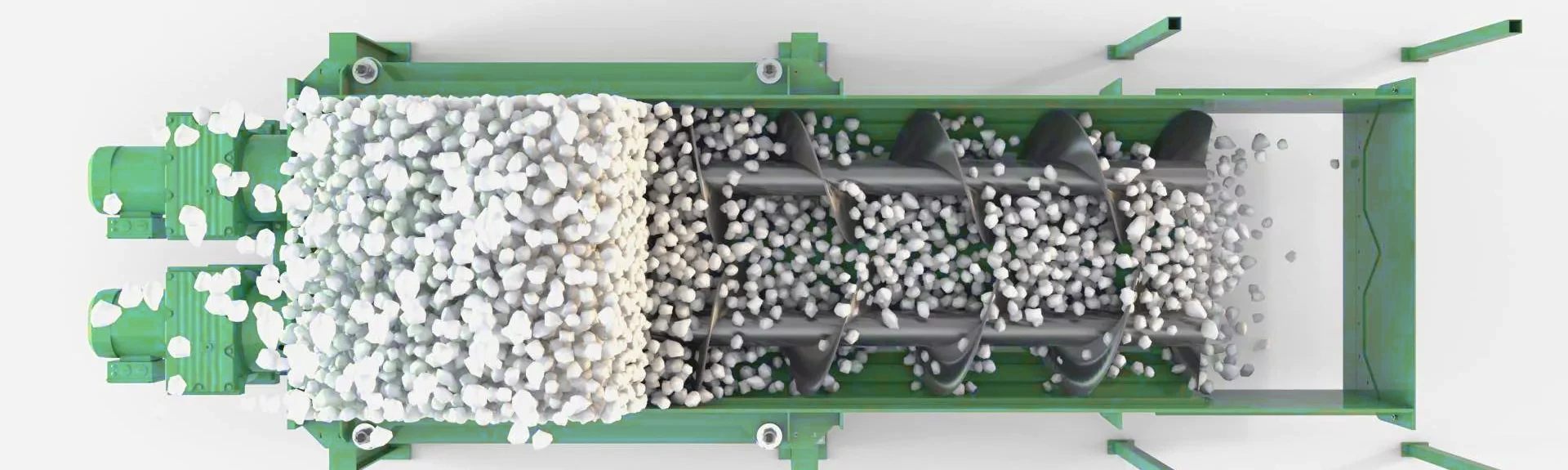

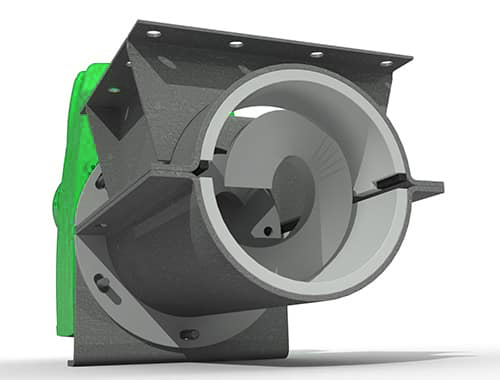

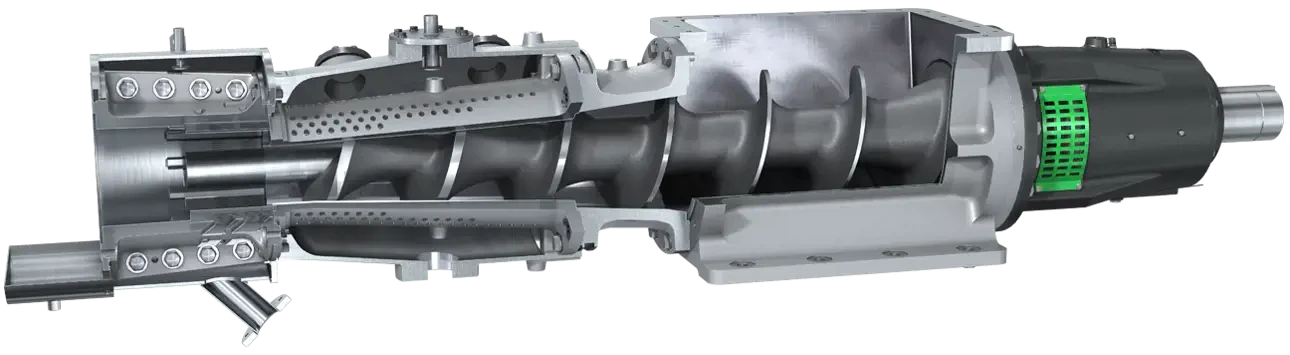

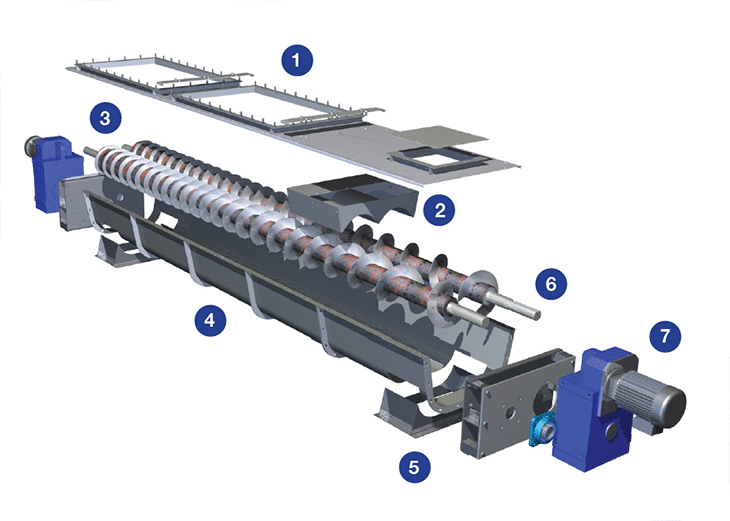

The screw feeder efficiently meters bulk solid materials ensuring performance of the plant. It consists of a helical screw that rotates inside a confinement channel. As the screw turns, it moves materials from the input end to the output end by pushing them along the trough. This process minimizes variations in flow rate and reduces the risk of blockages, even when dealing with abrasive materials.

The advantages of such systems include the continuous and controlled material flow, energy efficiency and low maintenance. Single screw, twin screw and special design models with variable pitches are available according to the needs of the user. While single screw systems are generally preferred in standard feeding processes, twin screw systems are suitable for applications requiring more precise and homogenous dosing.

| Model | Capacity (tons/hour) | Screw Diameter (mm) | Trough Length (mm) | Motor Power (kW) | Screw Speed (RPM) | Max Particle Size (mm) | Approx. Weight (kg) |

|---|---|---|---|---|---|---|---|

| SF-200 | 1 – 5 | 150 | 2000 | 1.5 | 50 | 10 | 600 |

| SF-300 | 5 – 10 | 200 | 2500 | 2.2 | 50 | 15 | 800 |

| SF-400 | 10 – 20 | 250 | 3000 | 3.0 | 45 | 20 | 1000 |

| SF-500 | 15 – 25 | 300 | 3500 | 4.0 | 45 | 25 | 1300 |

| SF-600 | 20 – 35 | 350 | 4000 | 5.5 | 40 | 30 | 1600 |

| SF-700 | 30 – 50 | 400 | 4500 | 7.5 | 40 | 35 | 1900 |

| SF-800 | 40 – 60 | 450 | 5000 | 9.0 | 35 | 40 | 2200 |

| SF-900 | 50 – 70 | 500 | 5500 | 11 | 35 | 50 | 2600 |

| SF-1000 | 60 – 80 | 550 | 6000 | 15 | 30 | 50 | 3000 |

| SF-1100 | 70 – 90 | 600 | 6500 | 18.5 | 30 | 50 | 3400 |

| SF-1200 | 80 – 100 | 650 | 7000 | 22 | 25 | 60 | 3800 |

| SF-1300 | 90 – 110 | 700 | 7500 | 30 | 25 | 60 | 4200 |

| SF-1400 | 100 – 120 | 750 | 8000 | 37 | 20 | 60 | 4600 |

| SF-1500 | 110 – 130 | 800 | 8500 | 45 | 20 | 60 | 5000 |

| SF-1600 | 120 – 150 | 900 | 9000 | 55 | 20 | 60 | 5500 |

NOTE: Our company manufactures systems in a wide range of capacities, from laboratory scale to industrial scale. To receive a price quote for your desired capacity, please send an email to

info@proses-makina.com