SPACE-EFFICIENT DESIGN

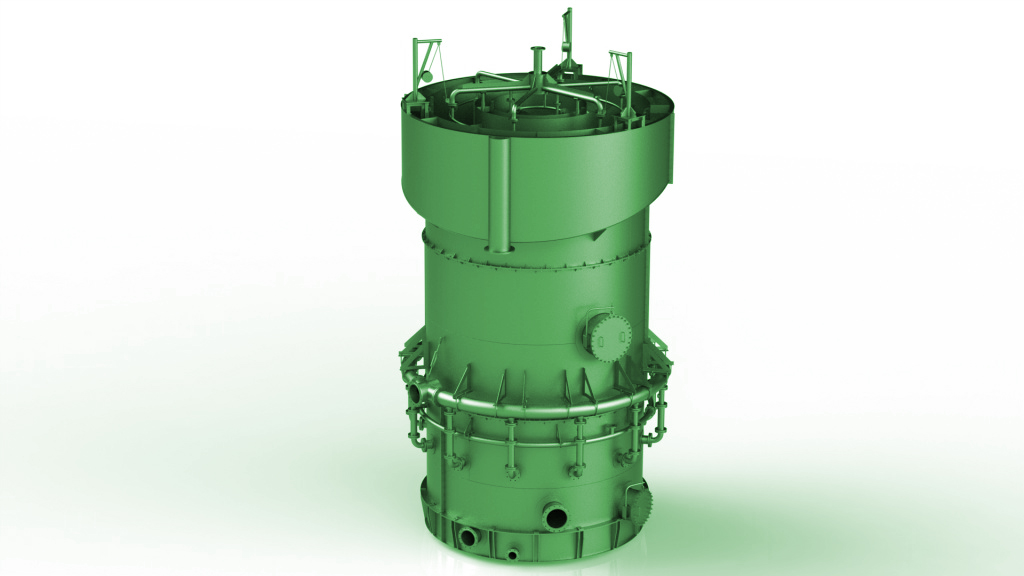

Column flotation cells are an essential technology in the mining industry, primarily used for the beneficiation of mineral ores. Their vertical, cylindrical design enhances the separation of valuable minerals from ore based on differences in physicochemical properties. These cells consist of a column body, feed inlet, air sparger, wash water system, and collection zone. Air bubbles, generated by the sparger, rise through the slurry, allowing hydrophobic mineral particles to attach to the bubbles and float to the surface. The wash water system ensures a cleaner froth by removing unwanted particles, improving concentrate purity. Column flotation cells offer significant advantages, such as improved recovery rates, higher concentrate grades, and reduced operating costs, due to better particle-bubble contact and more efficient separation processes.

Column flotation cells are widely utilized for various applications in the mining industry, including the separation of base metals like copper, lead, and zinc, as well as precious metals such as gold and silver. The space-efficient vertical design requires less floor space compared to traditional mechanical flotation cells, making them ideal for mineral processing plants with limited space. With the ability to handle large volumes of slurry and offer higher recovery rates, column flotation cells are an attractive solution for processing a wide range of ores. They provide a cost-effective, high-performance option for mineral beneficiation, improving overall plant efficiency while reducing energy consumption and reagent usage.

| Model | Column Height (m) | Column Diameter (mm) | Capacity (m³/h) | Air Flow Rate (m³/min) | Power Consumption (kW) | Weight (kg) |

|---|---|---|---|---|---|---|

| CFC-100 | 4 | 500 | 5 – 10 | 0.5 | 5 | 2500 |

| CFC-200 | 5 | 700 | 10 – 20 | 1.0 | 7.5 | 4000 |

| CFC-300 | 6 | 900 | 20 – 30 | 1.5 | 11 | 5500 |

| CFC-400 | 7 | 1100 | 30 – 45 | 2.0 | 15 | 7000 |

| CFC-500 | 8 | 1300 | 45 – 60 | 2.5 | 18.5 | 8500 |

| CFC-600 | 9 | 1500 | 60 – 80 | 3.0 | 22 | 10000 |

| CFC-700 | 10 | 1700 | 80 – 100 | 3.5 | 30 | 12000 |

| CFC-800 | 11 | 1900 | 100 – 120 | 4.0 | 37 | 14000 |

| CFC-900 | 12 | 2100 | 120 – 150 | 4.5 | 45 | 16000 |

| CFC-1000 | 13 | 2300 | 150 – 180 | 5.0 | 55 | 18000 |

| CFC-1100 | 14 | 2500 | 180 – 210 | 5.5 | 75 | 20000 |

| CFC-1200 | 15 | 2700 | 210 – 240 | 6.0 | 90 | 22000 |

| CFC-1300 | 16 | 2900 | 240 – 270 | 6.5 | 110 | 24000 |

| CFC-1400 | 17 | 3100 | 270 – 300 | 7.0 | 132 | 26000 |

| CFC-1500 | 18 | 3300 | 300 – 350 | 7.5 | 160 | 28000 |

NOTE: Our company manufactures systems in a wide range of capacities, from laboratory scale to industrial scale. To receive a price quote for your desired capacity, please send an email to

info@proses-makina.com