REDEFINING ROCK REDUCTION

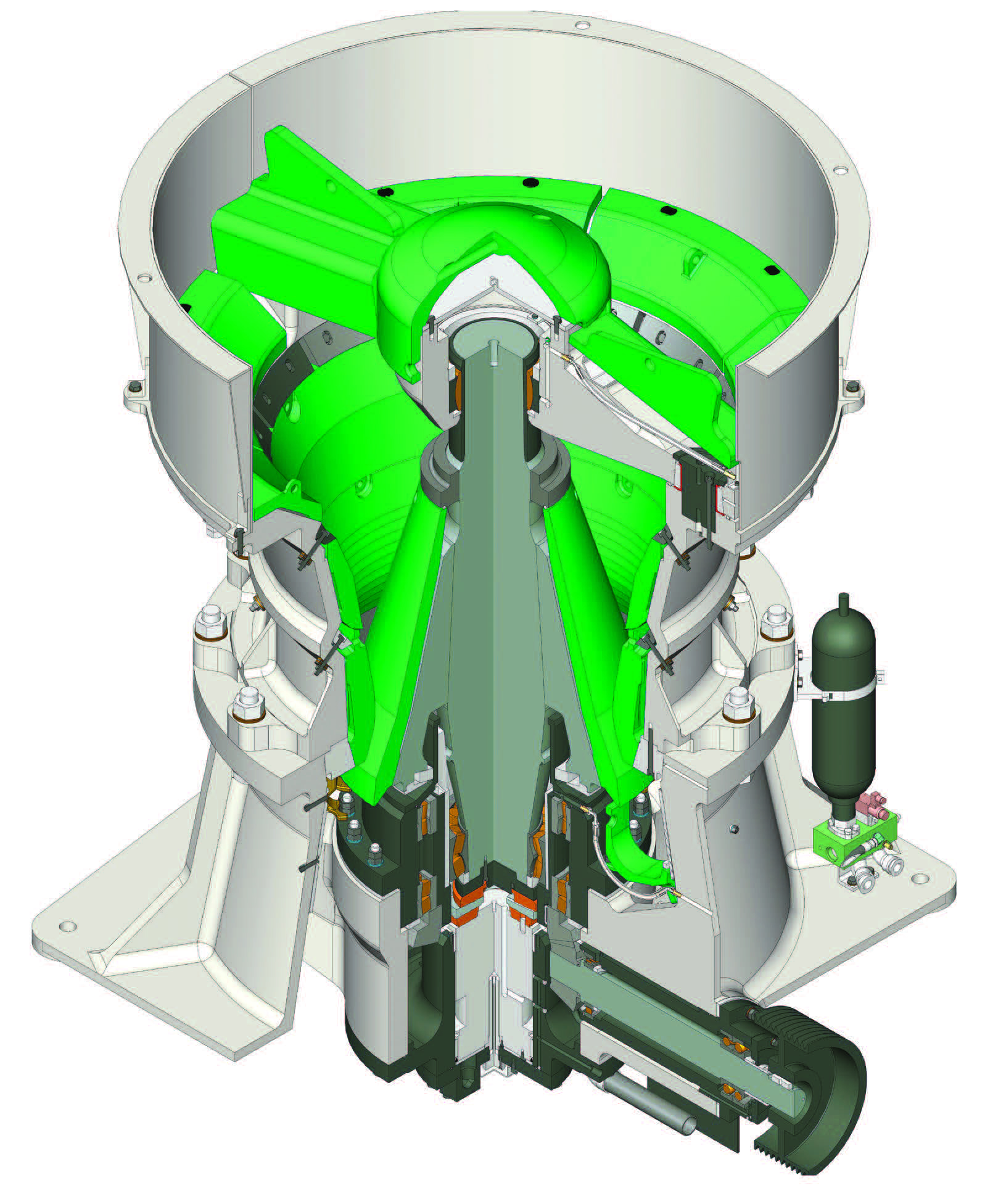

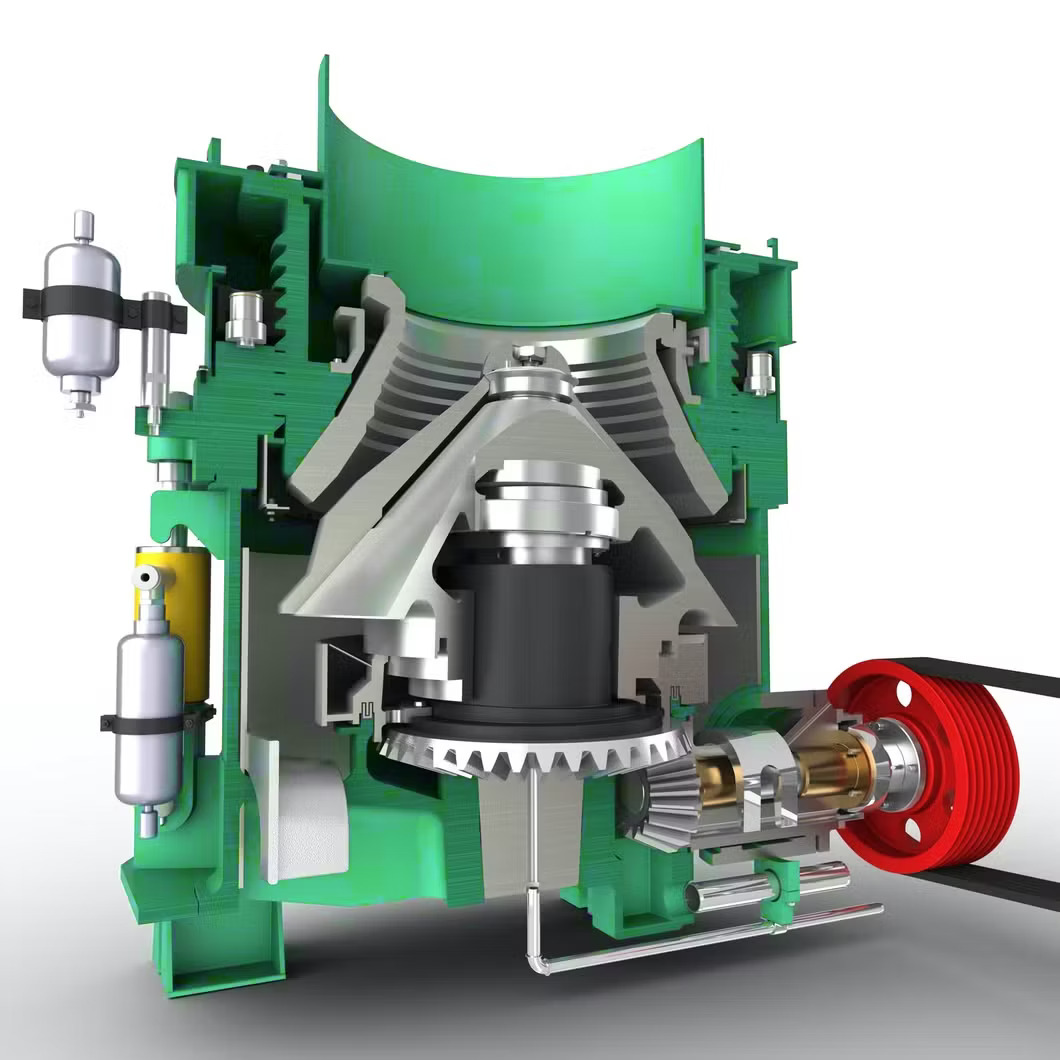

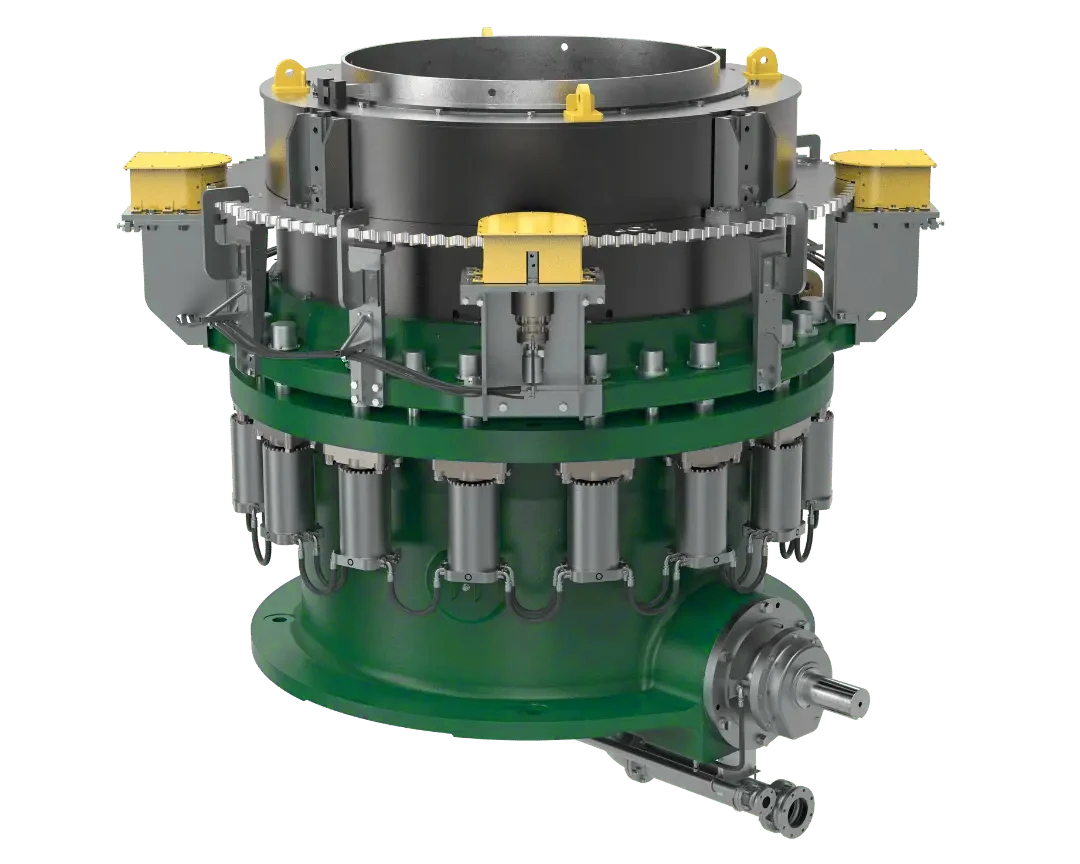

Cone Crusher is a versatile and efficient crushing solution designed for the reduction of various materials in mining and aggregate industries. Featuring a cone-shaped crushing chamber, the crusher ensures uniform particle size distribution, optimizing downstream processes. The hydraulic system provides precise control over the crusher settings, allowing for adjustments to accommodate different feed materials and achieve desired product sizes.

Proses Makina's Cone Crusher boasts a sturdy construction and advanced technology, offering high-performance crushing capabilities for challenging applications. It is used for secondary and tertiary crushing. They reduce ore diameters from as much as 250 mm to less than 10 mm. The machine's ability to maintain a constant product size, even under varying feed conditions, offers a significant advantage that contributes to the overall efficiency of the crushing process.

| Model | Capacity (tons/hour) | Feed Opening (mm) | Discharge Setting (mm) | Motor Power (kW) | Max Feed Size (mm) | Weight (kg) |

|---|---|---|---|---|---|---|

| CC-100 | 30 – 50 | 150 | 10 – 20 | 55 | 125 | 9500 |

| CC-200 | 50 – 80 | 175 | 10 – 25 | 75 | 150 | 11000 |

| CC-300 | 70 – 100 | 200 | 10 – 25 | 90 | 175 | 13000 |

| CC-400 | 90 – 130 | 215 | 12 – 30 | 110 | 185 | 15000 |

| CC-500 | 110 – 150 | 230 | 12 – 30 | 132 | 200 | 17000 |

| CC-600 | 130 – 180 | 250 | 15 – 35 | 160 | 220 | 19000 |

| CC-700 | 150 – 200 | 275 | 15 – 35 | 185 | 240 | 21000 |

| CC-800 | 180 – 220 | 300 | 18 – 40 | 200 | 260 | 23000 |

| CC-900 | 200 – 250 | 325 | 18 – 40 | 220 | 280 | 25000 |

| CC-1000 | 230 – 280 | 350 | 20 – 50 | 250 | 300 | 28000 |

| CC-1100 | 250 – 300 | 375 | 20 – 50 | 280 | 320 | 31000 |

| CC-1200 | 280 – 320 | 400 | 25 – 60 | 315 | 340 | 34000 |

| CC-1300 | 300 – 350 | 425 | 25 – 60 | 355 | 360 | 37000 |

| CC-1400 | 320 – 370 | 450 | 30 – 70 | 400 | 380 | 40000 |

| CC-1500 | 350 – 400 | 475 | 30 – 70 | 450 | 400 | 45000 |

NOTE: Our company manufactures systems in a wide range of capacities, from laboratory scale to industrial scale. To receive a price quote for your desired capacity, please send an email to

info@proses-makina.com