A belt feeder is designed to handle bulk materials such as ores, coal, aggregates, and minerals in a controlled and efficient manner. It consists of a belt s...

Smooth Flow without Loss

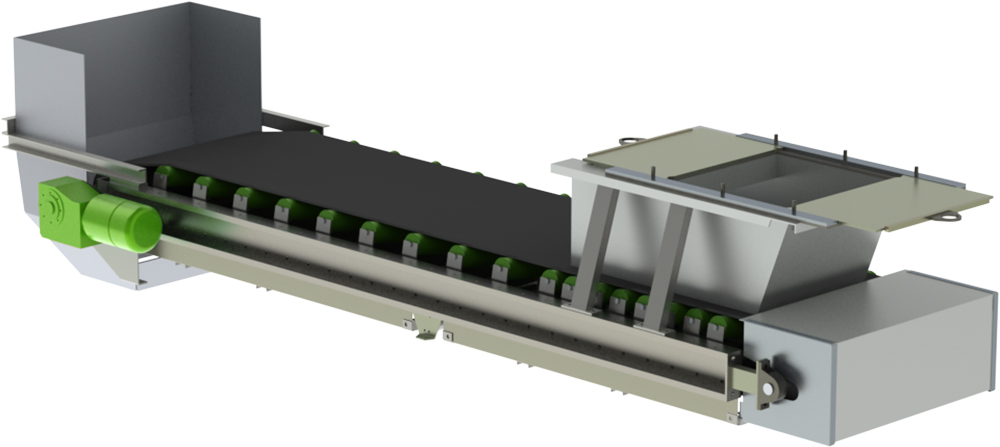

A belt feeder is designed to handle bulk materials such as ores, coal, aggregates, and minerals in a controlled and efficient manner. It consists of a belt supported by rollers or a slider bed, driven by a motorized pulley or gear system, allowing controlled and continuous material feed.

One key advantages of our belt feeder is its exceptional compatibility with a broad range of processed materials. It is specifically designed to endure abrasive, high-impact, and corrosive substances encountered in mining environments. Our system efficiently transports and discharges material with minimal spillage or blockage. The speed and configuration can be adjusted to meet the requirements of the process. The belt feeder is a critical piece of equipment for creating the most accurate and efficient process flow in facilities. By integrating an appropriate belt feeder, you can minimise losses in your plant. It ensures optimum traction and performance, even under fluctuating load conditions.

| Model | Capacity (tons/hour) | Belt Width (mm) | Belt Length (mm) | Motor Power (kW) | Belt Speed (m/s) | Max Lump Size (mm) | Approx. Weight (kg) |

|---|---|---|---|---|---|---|---|

| BF-300 | 20 – 50 | 500 | 3000 | 3.0 | 0.1 – 0.3 | 200 | 1200 |

| BF-400 | 40 – 80 | 600 | 3500 | 4.0 | 0.1 – 0.3 | 300 | 1400 |

| BF-500 | 60 – 120 | 700 | 4000 | 5.5 | 0.1 – 0.3 | 400 | 1600 |

| BF-600 | 80 – 160 | 800 | 4500 | 7.5 | 0.1 – 0.3 | 500 | 1800 |

| BF-700 | 100 – 200 | 900 | 5000 | 9.0 | 0.1 – 0.3 | 600 | 2000 |

| BF-800 | 150 – 250 | 1000 | 5500 | 11 | 0.1 – 0.3 | 700 | 2300 |

| BF-900 | 200 – 300 | 1100 | 6000 | 15 | 0.1 – 0.3 | 800 | 2600 |

| BF-1000 | 250 – 350 | 1200 | 6500 | 18.5 | 0.1 – 0.3 | 900 | 3000 |

| BF-1100 | 300 – 400 | 1300 | 7000 | 22 | 0.1 – 0.3 | 900 | 3400 |

| BF-1200 | 350 – 450 | 1400 | 7500 | 30 | 0.1 – 0.3 | 1000 | 3800 |

| BF-1300 | 400 – 500 | 1500 | 8000 | 37 | 0.1 – 0.3 | 1000 | 4200 |

| BF-1400 | 500 – 600 | 1600 | 8500 | 45 | 0.1 – 0.3 | 1000 | 4600 |

| BF-1500 | 600 – 700 | 1800 | 9000 | 55 | 0.1 – 0.3 | 1000 | 5000 |

| BF-1600 | 700 – 800 | 2000 | 9500 | 75 | 0.1 – 0.3 | 1000 | 5500 |

| BF-1800 | 800 – 900 | 2200 | 10000 | 90 | 0.1 – 0.3 | 1000 | 6000 |

NOTE: Our company manufactures systems in a wide range of capacities, from laboratory scale to industrial scale. To receive a price quote for your desired capacity, please send an email to

info@proses-makina.com