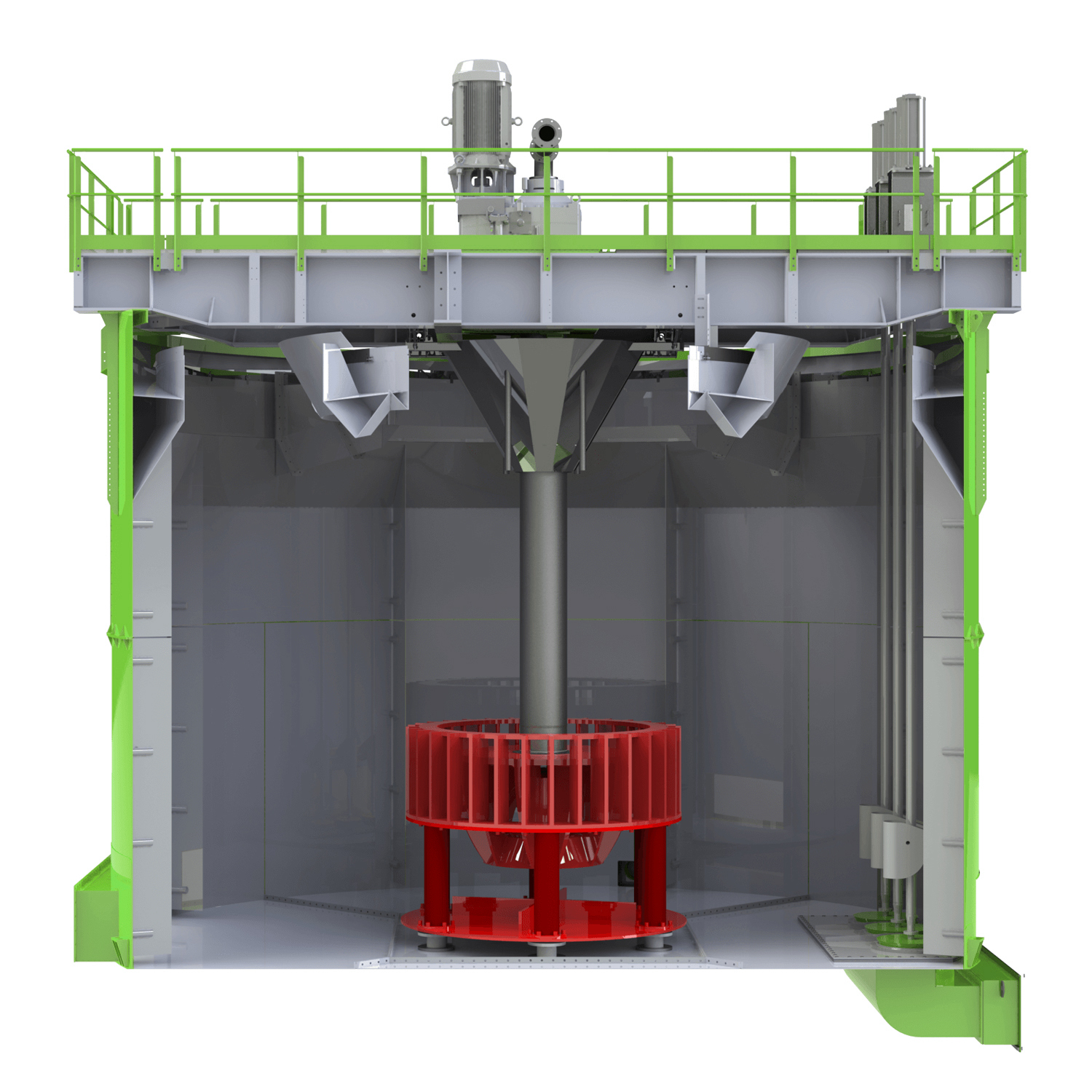

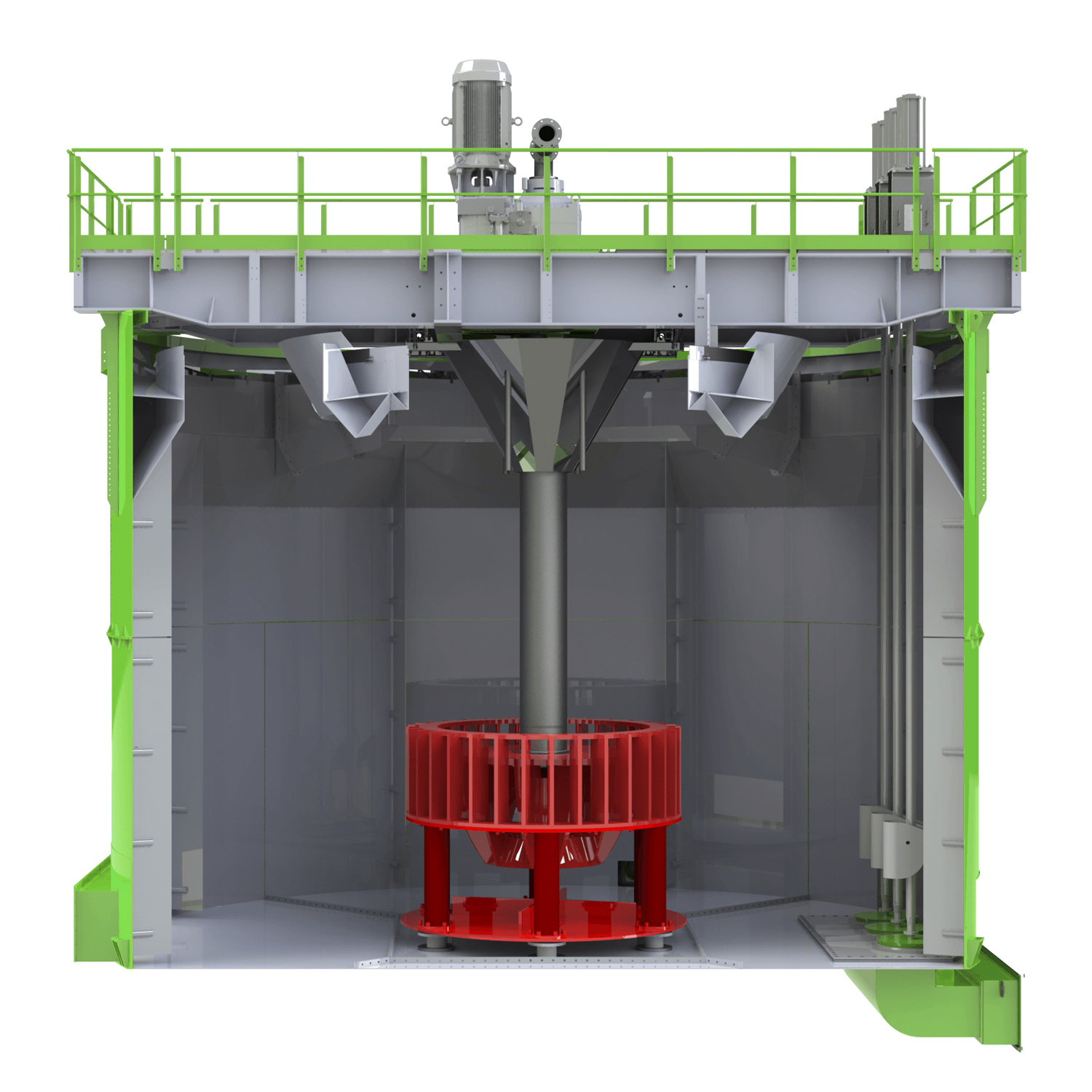

COMPACT AND MODULAR DESIGN

The Agitated Flotation Cell is engineered for the efficient separation of low-grade minerals, making it an essential solution for copper, lead, zinc, and precious metal processing. Its ability to handle slurries with diverse compositions ensures suitability not only for primary extraction plants but also for secondary beneficiation circuits. Additionally, the cell's capability to manipulate bubble size and agitation levels enhances the recovery of rare earth elements, effectively addressing complex mineralogical challenges. Thanks to its inherent adaptability, the Agitated Flotation Cell can be seamlessly integrated into both new installations and plant upgrades, delivering immediate performance improvements with minimal modifications. Its advanced agitation mechanism ensures optimal slurry-air mixing, precise bubble formation, and improved particle-bubble interaction, maximizing recovery efficiency. The cell features a high-performance aeration system that regulates airflow, minimizing turbulence for a smoother flotation process while reducing energy consumption.

The variable-speed drive system allows operators to adjust agitation intensity according to specific processing needs, optimizing operational flexibility. Constructed from high-quality, corrosion-resistant materials, the Agitated Flotation Cell guarantees durability and long-term reliability, even in the most demanding environments. Its compact, modular design enables easy integration into existing processing plants, offering a streamlined solution for enhanced flotation performance.

| Model | Cell Volume (m³) | Capacity (m³/min) | Impeller Diameter (mm) | Impeller Speed (RPM) | Motor Power (kW) | Air Flow Rate (m³/min) | Approx. Weight (kg) |

|---|---|---|---|---|---|---|---|

| AFC-100 | 1 | 0.2 – 0.5 | 400 | 280 | 5.5 | 0.3 | 1500 |

| AFC-200 | 2 | 0.4 – 1 | 500 | 260 | 7.5 | 0.6 | 2200 |

| AFC-300 | 3 | 0.6 – 1.5 | 600 | 240 | 11 | 0.9 | 3000 |

| AFC-400 | 4 | 0.8 – 2 | 700 | 220 | 15 | 1.2 | 4000 |

| AFC-500 | 5 | 1 – 2.5 | 800 | 200 | 18.5 | 1.5 | 5000 |

| AFC-600 | 6 | 1.2 – 3 | 900 | 180 | 22 | 1.8 | 6000 |

| AFC-700 | 8 | 1.6 – 4 | 1000 | 170 | 30 | 2.4 | 7500 |

| AFC-800 | 10 | 2 – 5 | 1100 | 160 | 37 | 3.0 | 9000 |

| AFC-900 | 12 | 2.4 – 6 | 1200 | 150 | 45 | 3.6 | 11000 |

| AFC-1000 | 14 | 2.8 – 7 | 1300 | 140 | 55 | 4.2 | 13000 |

| AFC-1100 | 16 | 3.2 – 8 | 1400 | 130 | 75 | 4.8 | 15000 |

| AFC-1200 | 18 | 3.6 – 9 | 1500 | 120 | 90 | 5.4 | 17000 |

| AFC-1300 | 20 | 4 – 10 | 1600 | 110 | 110 | 6.0 | 19000 |

| AFC-1400 | 22 | 4.4 – 11 | 1700 | 100 | 132 | 6.6 | 21000 |

| AFC-1500 | 25 | 5 – 12 | 1800 | 90 | 160 | 7.2 | 23000 |

NOTE: Our company manufactures systems in a wide range of capacities, from laboratory scale to industrial scale. To receive a price quote for your desired capacity, please send an email to

info@proses-makina.com