pH NEUTRALIZATION

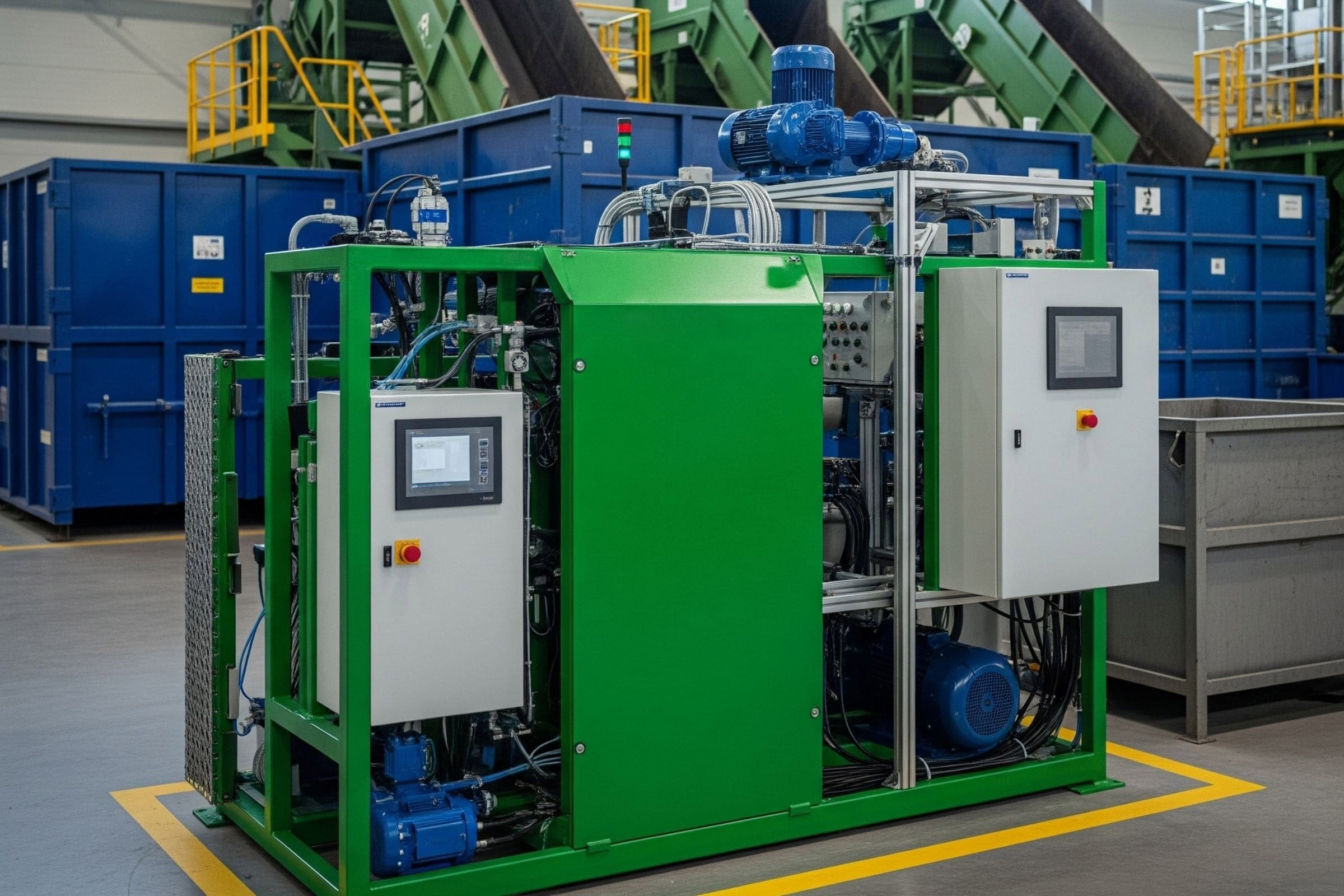

The Waste Acid Treatment System has been developed and successfully used by Proses Makina to control the waste acid or base generated at the end of hydrometallurgical operations. The waste acid produced at the end of PGMs refining processes can pose significant environmental risks. In accordance with national environmental regulations, it is mandatory to neutralize wastewater to safe levels. Neutralization units are used to treat waste liquids from refining systems by adding specific chemicals, thereby eliminating their harmful effects.

Neutralization units can be constructed from materials such as polypropylene (PP) or high-density polyethylene (HDPE), depending on the pH characteristics of the waste acid. It is essential that the manufactured units comply with environmental management standards, which must be verified through testing.

The general purpose of a pH neutralization plant is to neutralize the waste product solution before it is discharged into the environment. The required pH range for discharge from a wastewater treatment plant is typically between 7 and 8. This is important to protect rivers and aquatic life, and to prevent damage caused by corrosion.

Key features of the Waste Acid Treatment System include:

Ensuring the optimum pH range with an automatic feeding system

Contributing to the circular economy by reducing acid/base consumption through reuse after the neutralization process

Excellent integration of the neutralization system for the processes to be treated, including chemical preparation and sedimentation tanks

Providing gradual sedimentation operations to meet environmental limits

Achieving high separation rates through the filter press system.