PGMs PURIFICATION

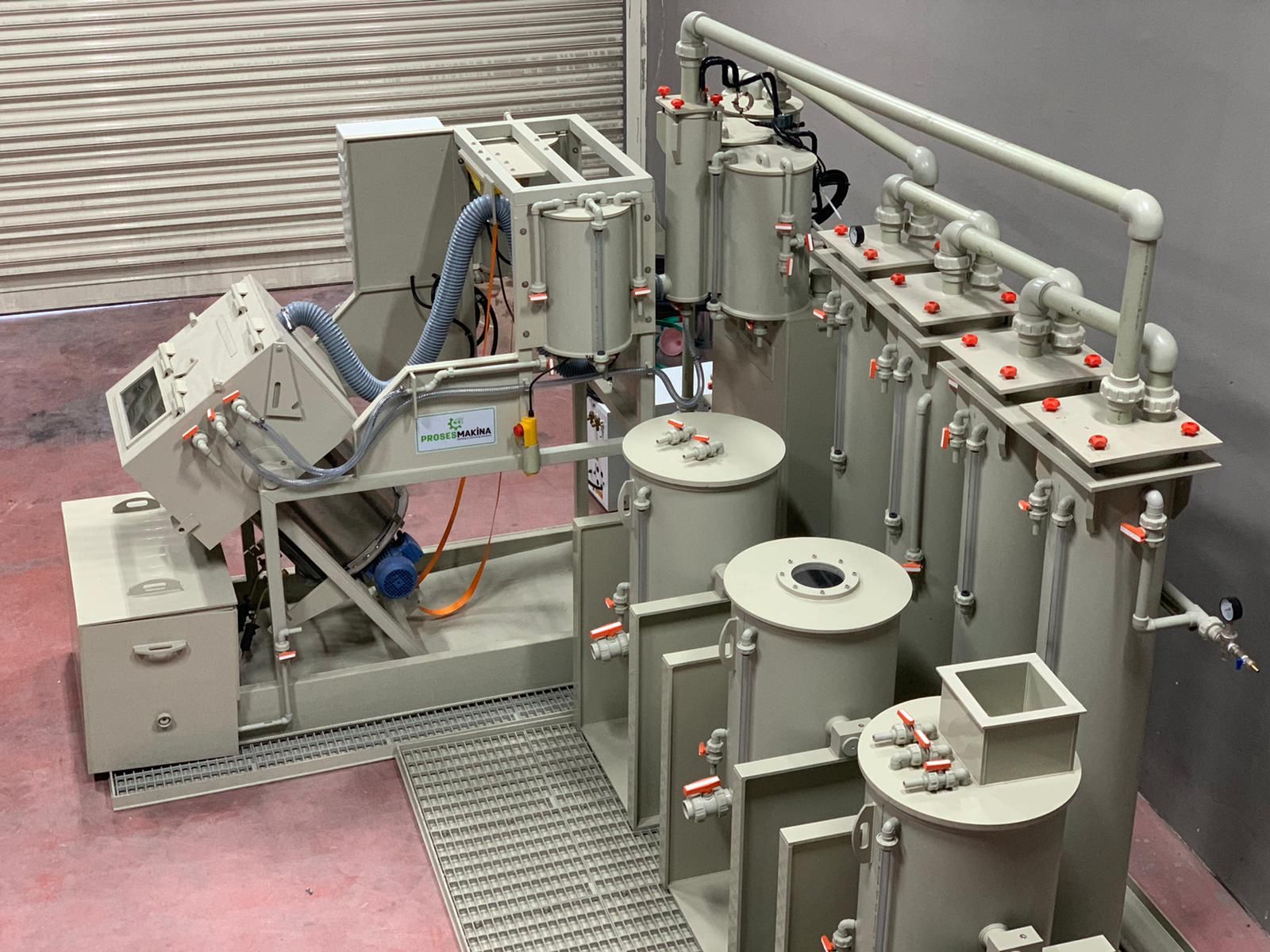

The Chemical Refining System is a vital stage in the process of recovering high-purity precious metals from spent catalytic converters. After the initial leaching process, the solution containing dissolved platinum group metals (PGMs) undergoes selective separation and purification steps to isolate metals like platinum, palladium, and rhodium. The goal of the chemical refining system is to ensure maximum purity and recovery efficiency through a series of chemical reactions, including pH adjustments, reduction reactions, and metal-specific treatments.

Selective Separation: The system uses a combination of precipitation steps and filtration to precisely isolate each metal from the leach solution, ensuring high-purity outputs.

Tailored Reactions: Chemical reactions such as pH adjustments and reduction processes are carefully controlled to meet the specific needs of the leach solution, optimizing the recovery of each precious metal.

High Purity and Efficiency: The chemical refining system ensures that recovered metals, including platinum, palladium, and rhodium, are refined to market-ready, high-purity standards, completing the recycling process with precision and sustainability.

Function: The Wheel Filter Equipment is designed for filtering solid or powder materials from liquid solutions, typically used in the refining process to separate impurities from valuable metals.

Mobility and Versatility: Equipped with a PP body, four wheels for mobility, and a diaphragm pump, the wheel filter can absorb and transfer solutions effectively.

Vacuum System: The system utilizes a vacuum generator, which can be equipped with either a liquid ring vacuum pump or a centrifugal pump, based on the customer’s needs.

Temperature Control: Includes a temperature control thermocouple to maintain stable water temperature, ensuring optimal filtration performance.

The Tumbler Reactor developed by Proses Makina is a key component for smelting and leaching in the chemical refining process, offering significant advantages:

Homogenization: Positioned at a specific angle, the tumbler reactor allows for better chemical contact with materials, accelerating the dissolution process and ensuring efficient reaction times.

Material Options: The reactor is available in different materials, including polypropylene, titanium, stainless steel, and static glass, offering flexibility based on the nature of the process and longevity of equipment.

Customized Efficiency: The system can be customized to maximize efficiency according to specific process requirements, ensuring optimal output.

Air Pollution and Contaminant Control: The system incorporates an air treatment system and neutralization unit to prevent contaminants and harmful fumes from being released during the reaction.

Vacuum Conditions: The reactor operates under vacuum conditions to ensure safety and efficiency, incorporating a speed control and dosing system for precise process management.

Heating System: There are options for both direct and indirect heating arrangements, enhancing the system’s versatility and capability to maintain optimal reaction conditions.

Together, these systems form a highly efficient and sustainable process for the recovery and refining of precious metals, optimizing both environmental impact and product quality throughout the refining cycle.