FINELY GRINDING

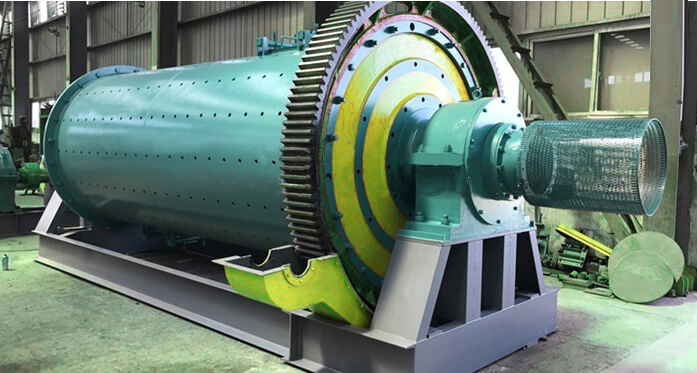

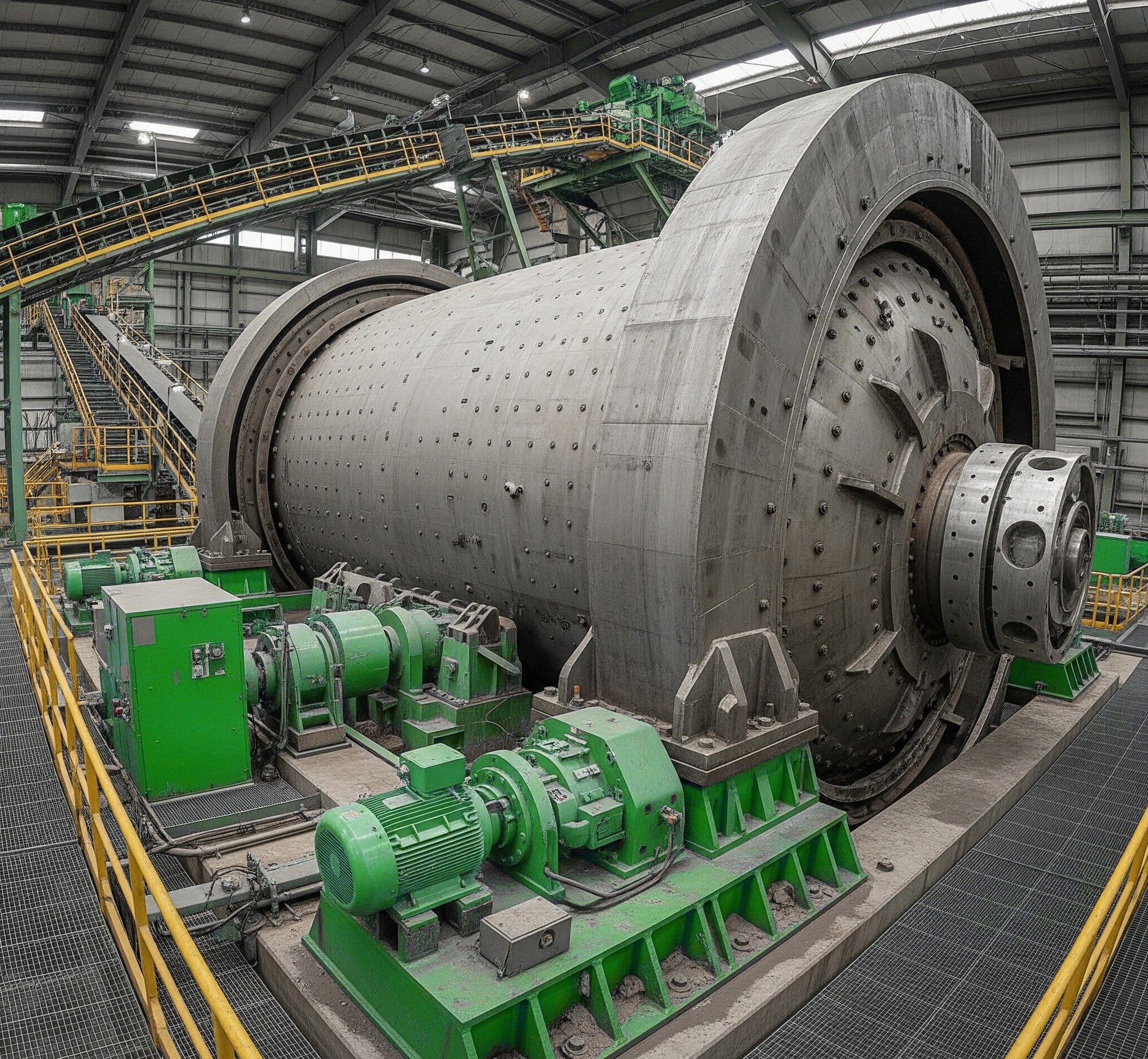

The ball mill is an efficient grinding machine that operates with metal balls of various sizes to grind materials and achieve homogeneous mixtures. Designed as a horizontal or slightly inclined cylinder, it is widely used in industries such as mining, ceramics, paint, and metal recycling. Its closed-system operation minimizes dust and environmental contamination risks. It is suitable for both dry and wet grinding processes and enables the production of nano-sized particles.

With high efficiency and suitability for large-scale production, it is an ideal solution for industrial applications. The composition of the grinding material can be adjusted as needed. However, energy consumption is relatively high, and the shape of the produced particles may not be perfectly uniform. Despite these limitations, its low cost and ease of implementation make the ball milling method an attractive choice for various manufacturing processes.

| Model | Drum Diameter (mm) | Drum Length (mm) | Capacity (tons/hour) | Rotating Speed (RPM) | Motor Power (kW) | Approx. Weight (kg) |

|---|---|---|---|---|---|---|

| BM-600 | 600 | 900 | 0.2 – 0.5 | 38 | 5.5 | 2000 |

| BM-900 | 900 | 1800 | 0.5 – 1.2 | 32 | 11 | 4000 |

| BM-1200 | 1200 | 2400 | 1 – 3 | 28 | 22 | 7500 |

| BM-1500 | 1500 | 3000 | 2 – 5 | 24 | 37 | 12000 |

| BM-1800 | 1800 | 3600 | 4 – 8 | 22 | 55 | 18000 |

| BM-2000 | 2000 | 4000 | 6 – 12 | 20 | 75 | 25000 |

| BM-2200 | 2200 | 4500 | 8 – 15 | 18 | 90 | 32000 |

| BM-2400 | 2400 | 5000 | 10 – 20 | 16 | 110 | 40000 |

| BM-2600 | 2600 | 5200 | 12 – 25 | 15 | 132 | 50000 |

| BM-2800 | 2800 | 5600 | 15 – 30 | 14 | 160 | 60000 |

| BM-3000 | 3000 | 6000 | 18 – 35 | 13 | 185 | 70000 |

| BM-3200 | 3200 | 6400 | 20 – 40 | 12 | 220 | 80000 |

| BM-3400 | 3400 | 6800 | 25 – 50 | 11 | 250 | 90000 |

| BM-3600 | 3600 | 7200 | 30 – 60 | 10 | 280 | 100000 |

| BM-3800 | 3800 | 7600 | 35 – 70 | 9 | 315 | 110000 |

NOTE: Our company manufactures systems in a wide range of capacities, from laboratory scale to industrial scale. To receive a price quote for your desired capacity, please send an email to

info@proses-makina.com