STRIKE ON HARDNESS

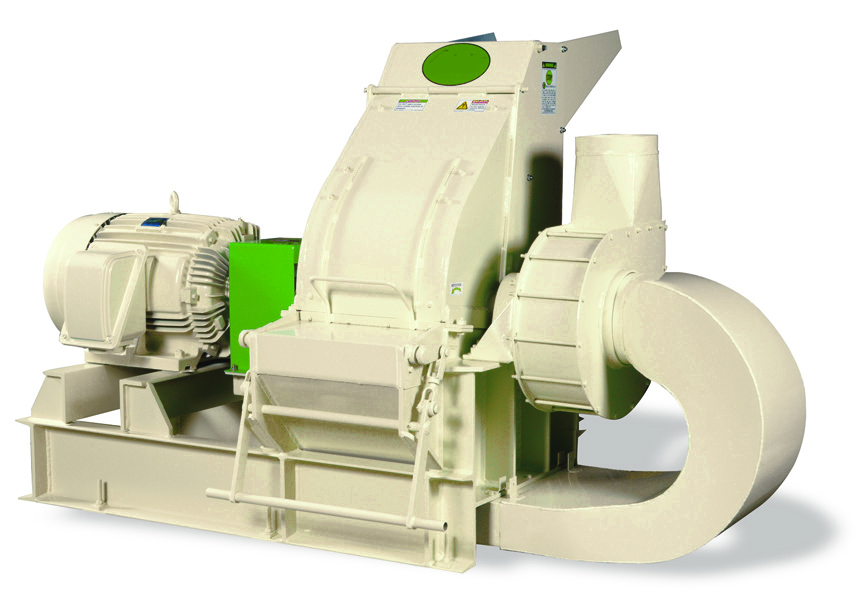

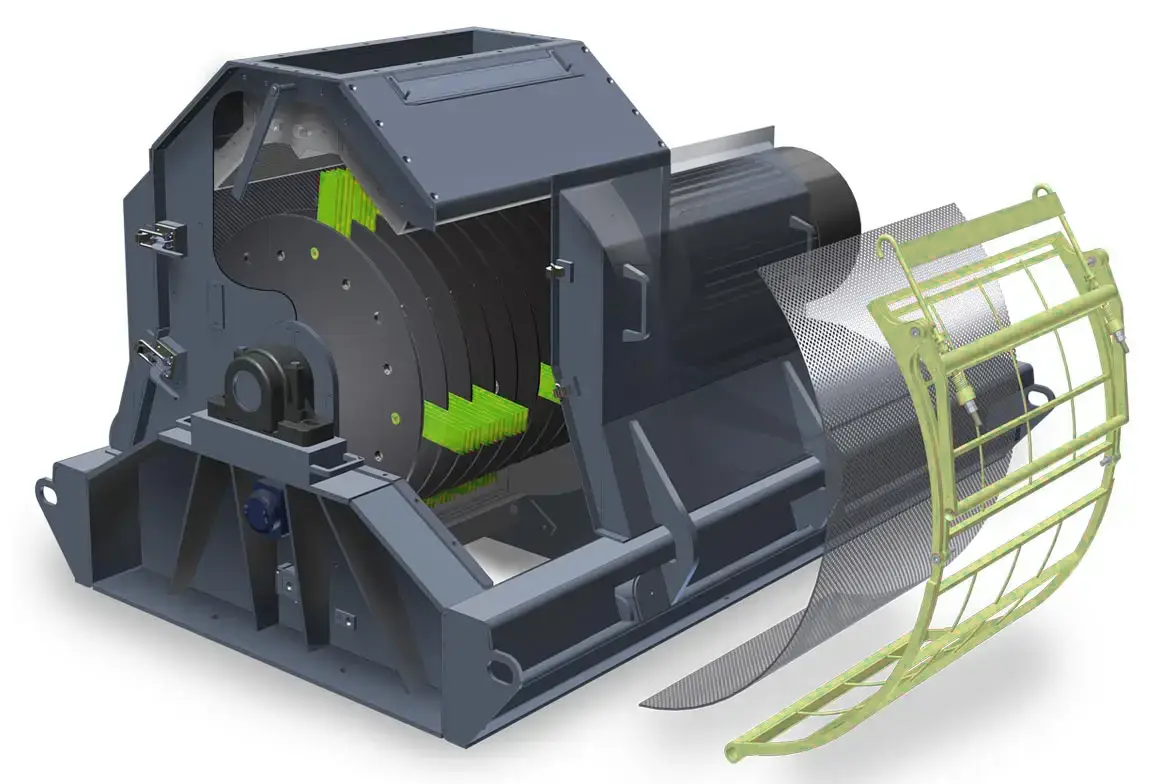

Hammer mills are widely used for mechanical preprocessing due to their ability to achieve high size reduction ratios and produce uniformly shaped particles. They operate by rapidly rotating hammers that impact materials, causing them to shatter. The material then strikes the inner breaker plate, further reducing its size. High-speed hammer mills with small-diameter rotors are preferred for fine grinding, while tip speed influences the particle trajectory and grinding efficiency. The screen opening size determines particle size and energy consumption, with smaller openings requiring more energy.

Larger particles are retained for further grinding, which increases size reduction efficiency but also leads to wear on the mill's interior. Different breakage patterns are observed between hard and soft materials; the formation of finer particles is associated with increased wear. The arrangement of the grinders affects the breakage mechanism, which in turn alters the particle distribution. The mill performance can be optimized in different ways depending on rotor speed and feed rate.

| Model | Rotor Diameter (mm) | Rotor Width (mm) | Capacity (tons/hour) | Rotor Speed (RPM) | Motor Power (kW) | Approx. Weight (kg) |

|---|---|---|---|---|---|---|

| HM-300 | 300 | 200 | 0.2 – 0.5 | 3000 | 5.5 | 800 |

| HM-400 | 400 | 300 | 0.5 – 1 | 2800 | 7.5 | 1200 |

| HM-500 | 500 | 400 | 1 – 2 | 2600 | 11 | 1800 |

| HM-600 | 600 | 500 | 2 – 3 | 2400 | 15 | 2500 |

| HM-700 | 700 | 600 | 3 – 5 | 2200 | 22 | 3200 |

| HM-800 | 800 | 700 | 4 – 7 | 2000 | 30 | 4000 |

| HM-900 | 900 | 800 | 6 – 9 | 1800 | 37 | 5000 |

| HM-1000 | 1000 | 900 | 8 – 12 | 1600 | 45 | 6200 |

| HM-1100 | 1100 | 1000 | 10 – 15 | 1500 | 55 | 7500 |

| HM-1200 | 1200 | 1100 | 12 – 18 | 1400 | 75 | 9000 |

| HM-1300 | 1300 | 1200 | 15 – 22 | 1300 | 90 | 11000 |

| HM-1400 | 1400 | 1300 | 18 – 25 | 1200 | 110 | 13000 |

| HM-1500 | 1500 | 1400 | 20 – 28 | 1100 | 132 | 15000 |

| HM-1600 | 1600 | 1500 | 22 – 32 | 1000 | 160 | 17000 |

| HM-1800 | 1800 | 1600 | 25 – 35 | 900 | 185 | 19000 |

NOTE: Our company manufactures systems in a wide range of capacities, from laboratory scale to industrial scale. To receive a price quote for your desired capacity, please send an email to

info@proses-makina.com