HIGH EFFICENCY AND DURABLE

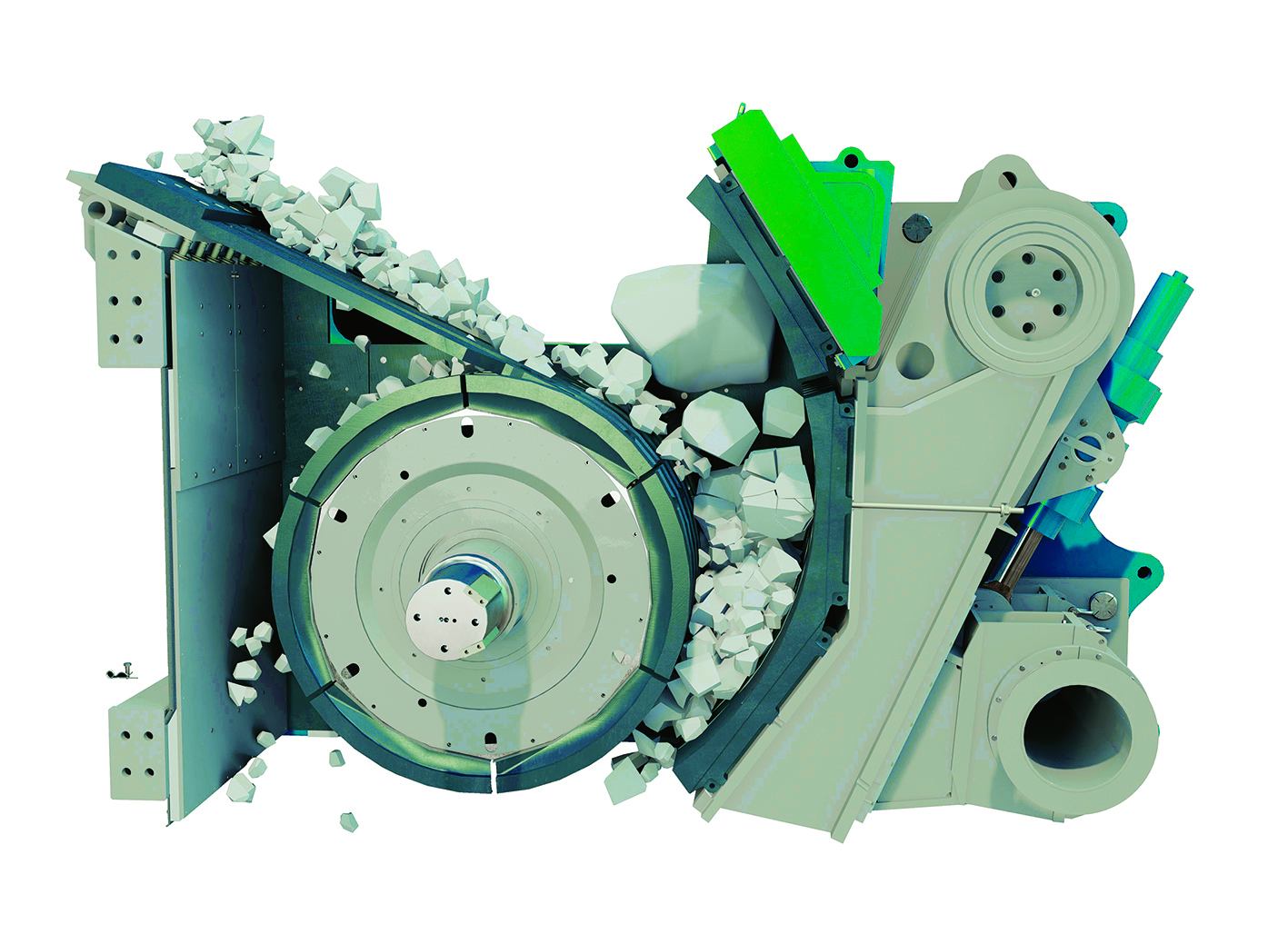

Roll crushers are widely used in the mining industry for their ability to efficiently handle materials that are friable, sticky, frozen, or less abrasive. They are particularly effective in processing limestone, coal, chalk, gypsum, phosphate, and soft iron ores, making them an ideal solution for various mining and mineral processing operations. Their capability to maintain consistent product size while minimizing fines makes them a preferred choice for many applications. Although roll crushers are not typically used as primary crushers for hard ores, they have been successfully applied as secondary crushers for softer ores like chalcocite and chalcopyrite. To ensure optimal performance, choke feeding is not recommended, as it can lead to irregular particle sizes. Both open and closed circuit crushing configurations are used, with closed circuits incorporating screening at mesh sizes smaller than the crusher setting to control the final product size precisely.

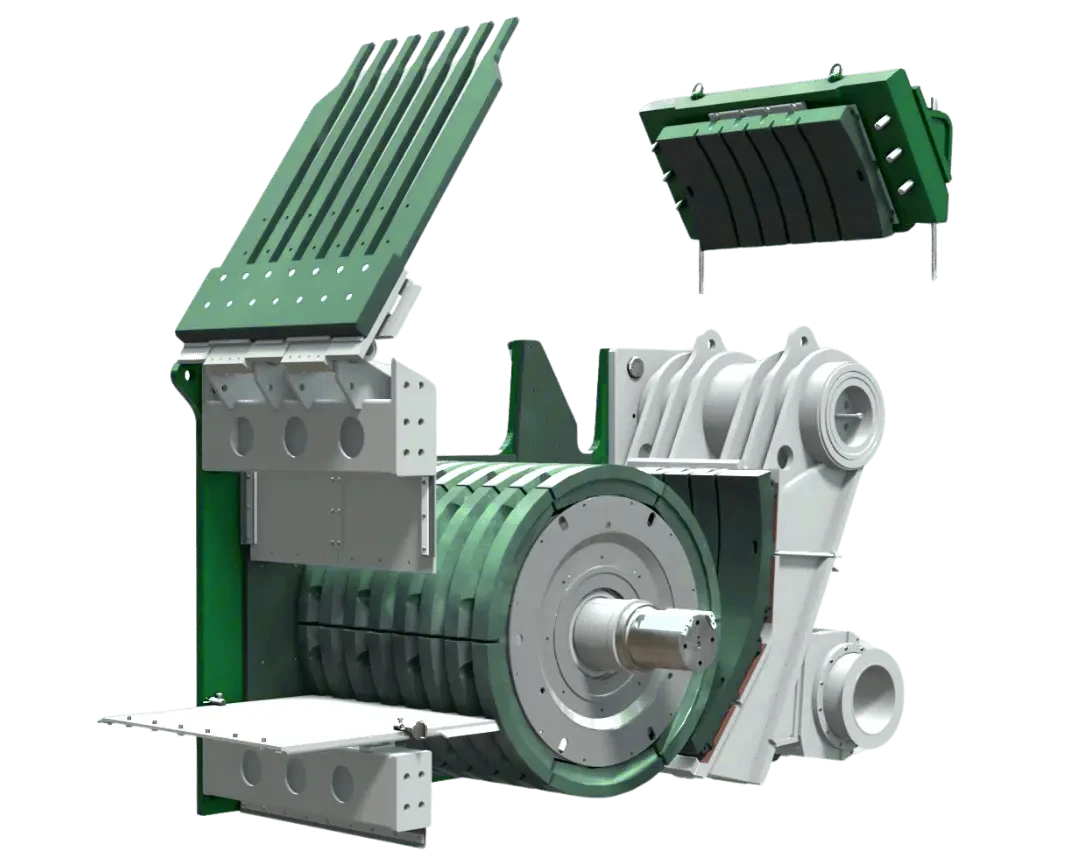

The working principle is straightforward: standard spring roll crushers use two horizontally rotating cylinders that apply compression force to crush the material in a single pressure action. Unlike jaw and cone crushers, which progressively break down material through repeated nipping, roll crushers achieve uniform particle size in a single step, ensuring efficiency and consistency.

| Model | Capacity (tons/hour) | Feed Size (mm) | Discharge Size (mm) | Roll Diameter (mm) | Motor Power (kW) | Approx. Weight (kg) |

|---|---|---|---|---|---|---|

| RC-100 | 5 – 15 | ≤50 | ≤5 | 300 | 15 | 2000 |

| RC-200 | 10 – 25 | ≤70 | ≤5 | 400 | 22 | 3000 |

| RC-300 | 20 – 40 | ≤90 | ≤5 | 500 | 30 | 4000 |

| RC-400 | 30 – 60 | ≤120 | ≤5 | 600 | 45 | 5000 |

| RC-500 | 50 – 80 | ≤150 | ≤5 | 700 | 55 | 6000 |

| RC-600 | 70 – 100 | ≤180 | ≤5 | 800 | 75 | 7000 |

| RC-700 | 90 – 120 | ≤200 | ≤5 | 900 | 90 | 8000 |

| RC-800 | 110 – 150 | ≤220 | ≤5 | 1000 | 110 | 9000 |

| RC-900 | 130 – 170 | ≤250 | ≤5 | 1100 | 132 | 11000 |

| RC-1000 | 150 – 190 | ≤280 | ≤5 | 1200 | 160 | 13000 |

| RC-1100 | 170 – 210 | ≤300 | ≤5 | 1300 | 185 | 15000 |

| RC-1200 | 190 – 230 | ≤320 | ≤5 | 1400 | 200 | 17000 |

| RC-1300 | 210 – 250 | ≤350 | ≤5 | 1500 | 220 | 19000 |

| RC-1400 | 230 – 270 | ≤380 | ≤5 | 1600 | 250 | 21000 |

| RC-1500 | 250 – 300 | ≤400 | ≤5 | 1700 | 280 | 23000 |

NOTE: Our company manufactures systems in a wide range of capacities, from laboratory scale to industrial scale. To receive a price quote for your desired capacity, please send an email to

info@proses-makina.com