HIGH-EFFICIENCY ORE ENRICHMENT

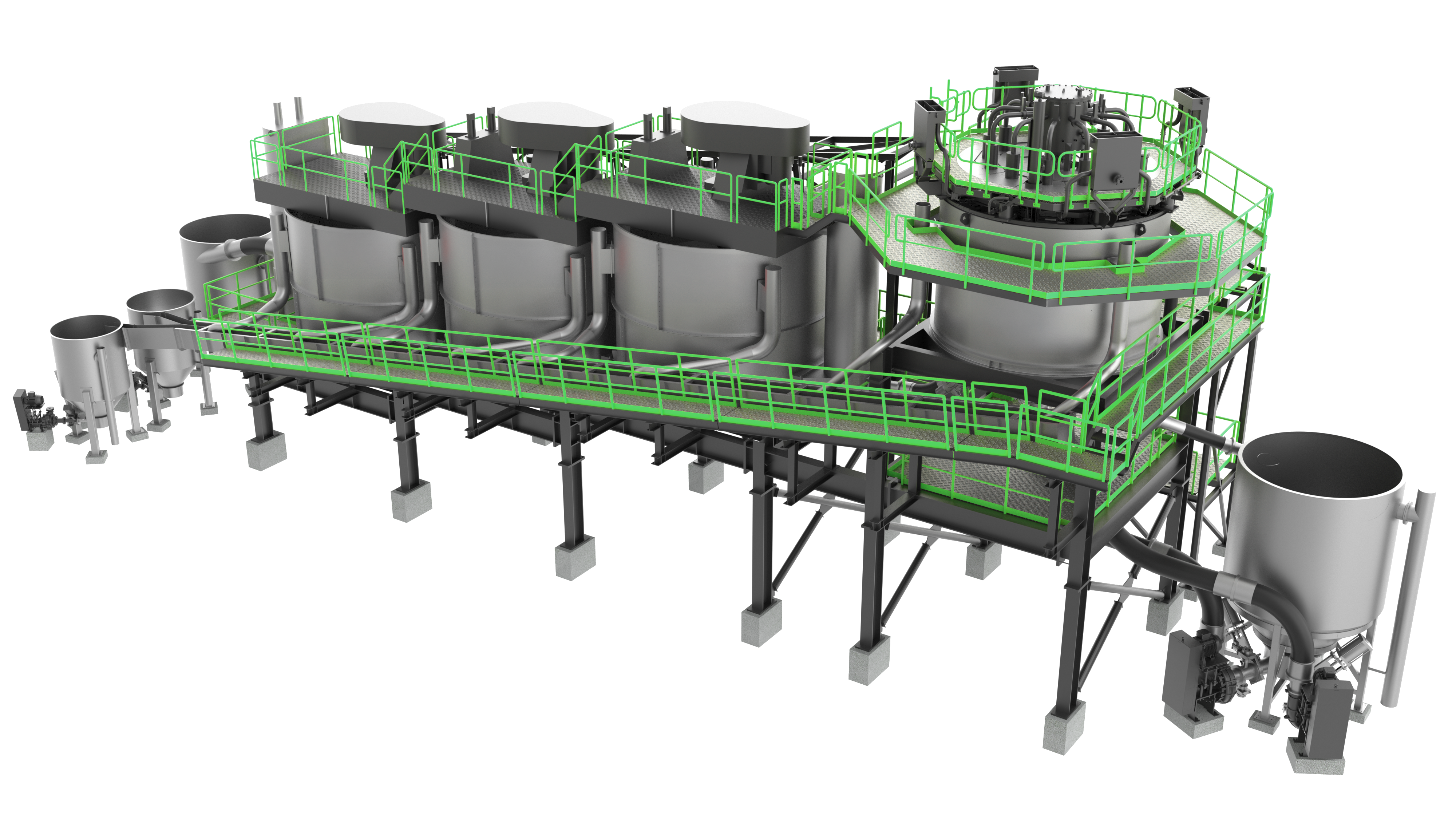

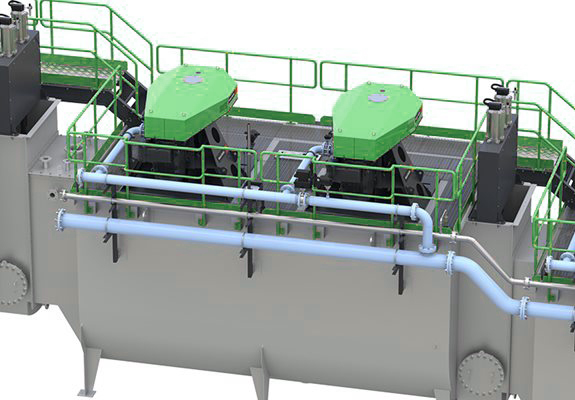

Outokumpu Flotation Cells offer the most advanced flotation technology in the industry, designed for maximum efficiency and durability in ore beneficiation processes. With an optimized tank design and a high-efficiency agitator system, these cells ensure homogeneous air distribution and excellent mixing, leading to superior flotation performance. The integration of energy-efficient motors and mechanisms reduces operational costs while minimizing environmental impact. Additionally, the modular structure allows for scalable configurations, making it adaptable to different capacity requirements. Advanced automation and control systems enable continuous process monitoring and optimization, ensuring consistent performance and maximum recovery rates.

The working mechanism of Outokumpu Flotation Cells is based on an innovative flotation process that optimizes mineral separation. The agitator system introduces air into the tank, forming fine bubbles that attach to mineral particles and bring them to the surface. This creates a stable froth layer, effectively separating valuable minerals from the ore slurry. Waste materials settle at the bottom and are discharged, while concentrate is collected efficiently. The flotation cells consist of a flotation tank, rotor and stator, air feed mechanism, and pulp feed and discharge system. The rotor profile is designed to balance hydrodynamic and static pressures, ensuring uniform air dispersion across the blade surfaces. The specialized blade design creates distinct zones for air distribution and slurry pumping, enhancing overall flotation efficiency and improving mineral recovery rates. By delivering superior flotation performance and energy savings, Outokumpu Flotation Cells provide an ideal solution for processing copper, gold, zinc, lead, and other metal ores, ensuring higher productivity and reduced operational costs.

| Model | Cell Volume (m³) | Capacity (m³/min) | Impeller Diameter (mm) | Impeller Speed (RPM) | Motor Power (kW) | Air Flow Rate (m³/min) | Approx. Weight (kg) |

|---|---|---|---|---|---|---|---|

| OC-100 | 1 | 0.3 – 0.6 | 400 | 280 | 5.5 | 0.4 | 1400 |

| OC-200 | 2 | 0.6 – 1.2 | 500 | 260 | 7.5 | 0.8 | 2200 |

| OC-300 | 3 | 0.9 – 1.8 | 600 | 240 | 11 | 1.2 | 3000 |

| OC-400 | 4 | 1.2 – 2.4 | 700 | 220 | 15 | 1.6 | 4000 |

| OC-500 | 5 | 1.5 – 3.0 | 800 | 200 | 18.5 | 2.0 | 5000 |

| OC-600 | 6 | 1.8 – 3.6 | 900 | 180 | 22 | 2.4 | 6000 |

| OC-700 | 8 | 2.4 – 4.8 | 1000 | 170 | 30 | 3.2 | 7500 |

| OC-800 | 10 | 3.0 – 6.0 | 1100 | 160 | 37 | 4.0 | 9000 |

| OC-900 | 12 | 3.6 – 7.2 | 1200 | 150 | 45 | 4.8 | 11000 |

| OC-1000 | 14 | 4.2 – 8.4 | 1300 | 140 | 55 | 5.6 | 13000 |

| OC-1100 | 16 | 4.8 – 9.6 | 1400 | 130 | 75 | 6.4 | 15000 |

| OC-1200 | 18 | 5.4 – 10.8 | 1500 | 120 | 90 | 7.2 | 17000 |

| OC-1300 | 20 | 6.0 – 12.0 | 1600 | 110 | 110 | 8.0 | 19000 |

| OC-1400 | 22 | 6.6 – 13.2 | 1700 | 100 | 132 | 8.8 | 21000 |

| OC-1500 | 25 | 7.5 – 15.0 | 1800 | 90 | 160 | 10.0 | 23000 |

NOTE: Our company manufactures systems in a wide range of capacities, from laboratory scale to industrial scale. To receive a price quote for your desired capacity, please send an email to

info@proses-makina.com