INDUSTRIAL SEPERATION

Specializing in machinery for metal refining and recovery processes, we provide a comprehensive range of industrial filtration solutions—including plate filter presses, vacuum filters, centrifugal separators, and crossflow filtration systems—engineered to deliver high-efficiency solid-liquid separation under the most demanding operational conditions.

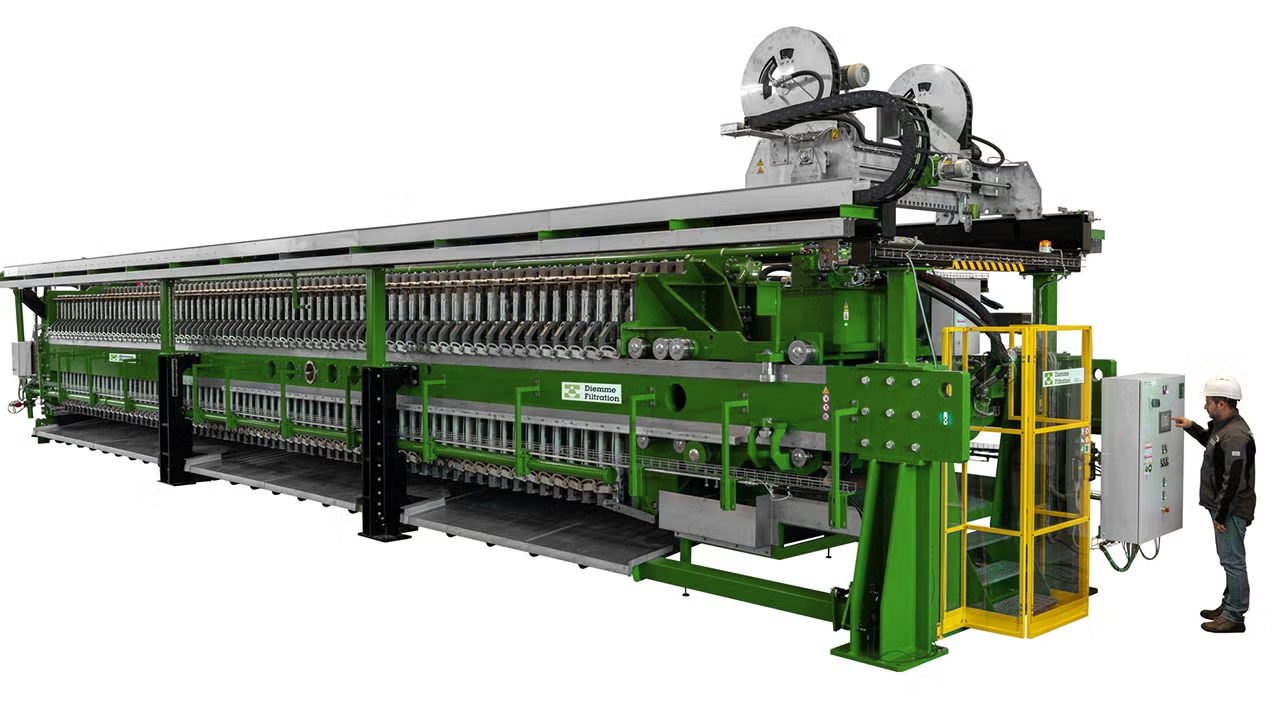

Pressure filters, such as plate filter presses, utilize externally applied pressure to drive the liquid through the filtration medium, leaving behind solid residues. These systems are ideal for applications requiring rapid and efficient separation under high flow conditions. Their ability to operate in both continuous and batch modes, as well as their compatibility with automated control systems, makes them especially valuable in metal refining environments where throughput and consistency are essential.

Vacuum filters operate by generating a pressure differential across the filter medium, effectively drawing the liquid phase through while retaining high concentrations of solids. These filters are widely used in mineral and metal processing applications, particularly where large slurry volumes must be handled efficiently and continuously. Their robust design and operational simplicity make them well-suited for aggressive process conditions.

Centrifugal filters employ centrifugal force to separate fine metal particles and sludge from liquids with high efficiency. By rotating at high speeds, these systems achieve excellent dewatering performance and produce solid outputs with low residual moisture. Their continuous operation capability and compact footprint make them advantageous for refining facilities requiring high-throughput separation and minimal downtime.

Crossflow filtration systems, also known as tangential flow filters, direct the process stream parallel to the filter surface. This configuration minimizes fouling and allows longer operational cycles, especially beneficial in closed-loop metal recovery systems or electrolyte purification. They are particularly effective in ultrafiltration and nanofiltration applications where high purity and stable membrane performance are critical.

The selection of the optimal filtration system depends on several key parameters, including particle size distribution, solids concentration, fluid characteristics (viscosity, temperature, corrosiveness), target filtration rate, and integration with automated process lines. Our engineering team delivers fully customized filtration solutions—from modular pre-filtration units to advanced, automated systems—designed to improve operational efficiency, enhance metal recovery rates, and reduce maintenance demands across a wide range of metallurgical applications.

| Model | Filter Area (m²) | Plate Size (mm) | Number of Plates | Chamber Volume (L) | Max Pressure (MPa) | Motor Power (kW) | Approx. Weight (kg) |

|---|---|---|---|---|---|---|---|

| FP-10 | 10 | 500 x 500 | 10 | 120 | 0.6 | 2.2 | 1200 |

| FP-20 | 20 | 630 x 630 | 20 | 300 | 0.6 | 3 | 1800 |

| FP-30 | 30 | 800 x 800 | 25 | 550 | 0.6 | 4 | 2500 |

| FP-40 | 40 | 800 x 800 | 30 | 750 | 0.6 | 4 | 3200 |

| FP-50 | 50 | 870 x 870 | 35 | 950 | 0.6 | 5.5 | 4000 |

| FP-60 | 60 | 870 x 870 | 40 | 1200 | 0.6 | 5.5 | 4700 |

| FP-70 | 70 | 1000 x 1000 | 45 | 1500 | 0.6 | 7.5 | 5500 |

| FP-80 | 80 | 1000 x 1000 | 50 | 1800 | 0.6 | 7.5 | 6300 |

| FP-90 | 90 | 1250 x 1250 | 55 | 2200 | 0.6 | 11 | 7500 |

| FP-100 | 100 | 1250 x 1250 | 60 | 2500 | 0.6 | 11 | 8500 |

| FP-110 | 110 | 1250 x 1250 | 65 | 2800 | 0.6 | 11 | 9500 |

| FP-120 | 120 | 1500 x 1500 | 70 | 3200 | 0.6 | 15 | 10500 |

| FP-130 | 130 | 1500 x 1500 | 75 | 3500 | 0.6 | 15 | 11500 |

| FP-140 | 140 | 1500 x 1500 | 80 | 3800 | 0.6 | 15 | 12500 |

| FP-150 | 150 | 1500 x 1500 | 85 | 4200 | 0.6 | 18.5 | 13500 |

NOTE: Our company manufactures systems in a wide range of capacities, from laboratory scale to industrial scale. To receive a price quote for your desired capacity, please send an email to

info@proses-makina.com