In an era where the demand for high purity metals is surging, industries are seeking innovative solutions to enhance their metal refining processes. Introducing our Improved Pyrometallurgy Solutions, designed to meet the growing challenge of high-purity metal production. These advancements not only optimize metal refining but also ensure superior quality that aligns with market standards. As we delve deeper into the significance of high-purity metals and the pyrometallurgical processes that yield them, our solutions stand out with key packages tailored for enhanced efficiency and purity. Discover how our unique approach differentiates us in the industry and the success stories that highlight our transformative impact on metal production practices. Join us as we explore the future of metallurgical innovations and the pivotal role they play in today’s competitive landscape.Discover advanced pyrometallurgy solutions for high-purity metal production, their market significance, and transformative success stories in metal refining.

Improved Pyrometallurgy Solutions for High-Purity Metal Production

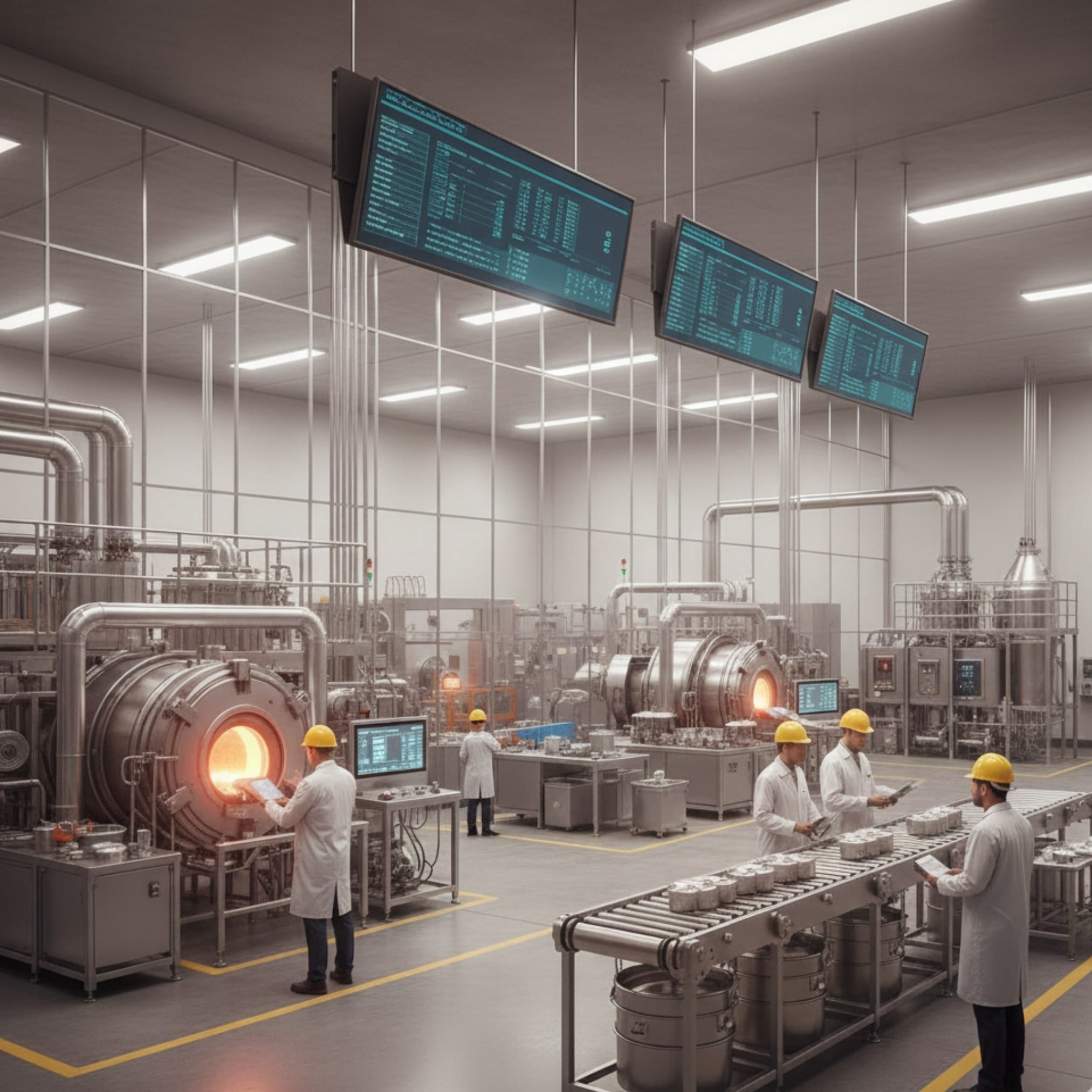

The realm of metal refining is undergoing a transformative phase through the adoption of Improved Pyrometallurgy Solutions for High-Purity Metal Production. These innovative approaches not only enhance recovery rates but also significantly minimize impurities, ensuring that the final product meets stringent industry standards. By diving into the intricacies of these advanced techniques, we uncover the beneficial mechanisms that drive efficiency.

An integral component of these solutions is the optimization of temperature and reaction conditions within the pyrometallurgical process. By carefully controlling these variables, producers can facilitate more efficient smelting, leading to higher purity levels in the resultant metals. Moreover, the integration of cutting-edge technology aids in real-time monitoring and adjustment, fostering a more responsive and adaptable refining environment.

Another key advantage of adopting Improved Pyrometallurgy Solutions for High-Purity Metal Production lies in their capability to process complex ores and recycle metal-bearing waste effectively. This not only stretches the boundaries of what can be refined but also promotes sustainable practices by reducing the necessity for new raw materials. The circular economy approach in metal production becomes a viable reality through these advanced methodologies.

The shift towards improved methods in pyrometallurgy highlights a commitment to quality and innovation in metal refining. As demand for high-purity metals continues to soar across industries, leveraging these solutions positions manufacturers at the forefront of market competitiveness and environmental responsibility.

The Significance Of High-Purity Metal Production In Today’s Market

In an era where technology and sustainability are paramount, the demand for high-purity metals is witnessing unprecedented growth. Industries ranging from electronics to renewable energy depend on these metals for performance, durability, and efficiency. The significance of high-purity metal production largely stems from its crucial role in enhancing the quality of end products while reducing environmental impacts.

First and foremost, the electronics sector thrives on high-purity metals, particularly as devices become increasingly sophisticated. For instance, applications in semiconductors and wiring require metals with minimal impurities to ensure optimal conductivity and functionality. Improved Pyrometallurgy Solutions for High-Purity Metal Production addresses this need by ensuring the extraction processes yield metals that comply with strict quality standards.

Moreover, high-purity metals contribute significantly to the advancement of green technologies. The renewable energy sector, for example, relies heavily on materials such as high-purity silver and indium used in solar panels and batteries. These applications necessitate metals that not only possess superior physical properties but also fulfill stringent regulatory requirements, thereby paving the way for a sustainable future.

Additionally, the pharmaceutical and aerospace industries are increasingly prioritizing high-purity metal production. In pharmaceuticals, metals must meet rigorous health standards, while in aerospace, the need for lightweight yet resilient materials further emphasizes the importance of metal purity. By integrating Improved Pyrometallurgy Solutions for High-Purity Metal Production, these industries can enhance their manufacturing processes significantly.

The significance of high-purity metal production in today’s market cannot be overstated. Companies that leverage improved pyrometallurgical solutions not only stay ahead of regulatory demands but also innovate efficiently, ultimately engaging consumers who value quality and sustainability in their products.

Understanding The Pyrometallurgical Process And Its Advantages

The pyrometallurgical process is a critical method in refining metals, harnessing the power of high temperatures to extract valuable metals from ores. This technique involves several stages, including roasting, smelting, and refining, to achieve highly efficient metal recovery and production. Let's delve deeper into how this process works and the benefits it brings to the industry.

During the initial stage of roasting, ores are heated in the presence of air to oxidize impurities, essentially preparing the materials for the smelting phase. Following this, the smelting process involves melting the ore in a furnace, where chemical reactions occur. Fluxes are typically added to facilitate the separation of metal from impurities, resulting in a molten metal that can be further refined. Finally, refining techniques such as electrolytic or chemical processes are employed to achieve the desired high purity levels.

Leveraging Improved Pyrometallurgy Solutions for High-Purity Metal Production brings numerous advantages that set it apart from other metallurgical processes. Firstly, this method excels in recovering metals at high yields, significantly minimizing wastage and maximizing resource utilization. Secondly, the tailored approaches in Improved Pyrometallurgy Solutions for High-Purity Metal Production allow for enhanced control over the process parameters, enabling the production of metals with superior quality and purity standards.

Moreover, the thermal energy required in pyrometallurgy can be efficiently harnessed, making the process more energy-efficient when implemented with the right advancements. This efficient management of energy resources not only reduces operational costs but also minimizes the environmental impact associated with metal production.

Understanding the pyrometallurgical process highlights its robust capability for producing high-purity metals. The technological advancements embedded in Improved Pyrometallurgy Solutions for High-Purity Metal Production pave the way for sustainable practices and enhanced economic viability in the metal refining industry.

Key Packages For Enhanced Pyrometallurgy And Metal Purity

Our enhanced pyrometallurgy solutions offer a comprehensive suite of packages specifically designed to optimize the metal refining process, ensuring the production of high-purity metals with unparalleled efficiency. Each package package is tailored to meet the unique needs of our clients, integrating the latest advancements in pyrometallurgy technology.

One of the key components of our offerings is the Improved Pyrometallurgy Solutions for High-Purity Metal Production, which includes state-of-the-art furnace systems, advanced refining techniques, and customized chemical treatments. These technologies not only enhance the purity levels of the metals produced but also significantly reduce processing times.

Additionally, our packages focus on sustainability and cost-effectiveness. By incorporating energy-efficient solutions and waste-reduction practices, we help our clients achieve their production goals while minimizing environmental impact. Our commitment to quality ensures that every client receives tailored solutions that translate into higher yields and better metal quality.

Furthermore, our dedicated support team works closely with clients throughout the entire refining process, providing expert guidance and innovative solutions that address complex challenges. This ensures that our clients benefit from continuous improvement and consistent results in their high-purity metal production processes.

Differentiators Of Our Improved Pyrometallurgy Solutions

Our Improved Pyrometallurgy Solutions for High-Purity Metal Production stand out in the industry due to several key differentiators that enhance both efficiency and output quality. These differentiators stem from our commitment to innovation, comprehensive expertise, and customer-focused approaches.

- Advanced Technology Integration: We utilize cutting-edge technologies, such as automated monitoring systems and AI-driven analytics, to optimize the pyrometallurgical process. This not only increases precision but also enhances operational efficiency.

- Tailored Solutions: Understanding that every client has unique requirements, our solutions are customizable. We work closely with each customer to develop processes that suit their specific metal production needs, ensuring superior outcomes.

- Expertise in High-Purity Metal Production: Our team comprises industry veterans who bring expansive knowledge and hands-on experience in the field of pyrometallurgy. This ensures that our solutions are not only effective but also align with the latest market trends and standards.

- Environmental Considerations: Our solutions prioritize sustainable practices, minimizing waste and emissions. We implement eco-friendly techniques, ensuring our clients meet social and regulatory compliance while maintaining high production standards.

- Integrated Support and Training: We offer ongoing support and training for our clients’ staff, ensuring they fully understand and can operate our systems optimally. This hands-on approach empowers teams and maximizes production efficiency.

By choosing our Improved Pyrometallurgy Solutions for High-Purity Metal Production, clients can enjoy elevated production capabilities and contribute to a more sustainable metal production landscape.

Success Stories: Transforming High-Purity Metal Production Practices

In the rapidly evolving landscape of metal refining, our Improved Pyrometallurgy Solutions for High-Purity Metal Production have significantly impacted several industries. Our expertise and innovative approaches have not only optimized the processes but have also addressed challenges faced by our clients in achieving metal purity. Here, we highlight a few success stories that demonstrate our commitment to excellence and the tangible results our solutions deliver.

Case Study 1: Electronics Industry

One of our client companies, a leading manufacturer of electronic components, faced issues with the quality of metals used in their production. By implementing our advanced pyrometallurgical techniques, they experienced a substantial increase in metal purity levels. This led to improved electrical conductivity and product reliability, ultimately enhancing their competitive edge in the market.

Case Study 2: Aerospace Sector

In the aerospace sector, stringent requirements for material quality are critical. We collaborated with a prominent aerospace manufacturer to refine their metal extraction processes. Utilizing our Improved Pyrometallurgy Solutions for High-Purity Metal Production, they achieved significant reductions in impurities and increased the yield of premium-grade materials, which resulted in safer and more efficient aircraft components.

Case Study 3: Renewable Energy

Another notable success story comes from a renewable energy company that relied heavily on high-purity metal for solar panel production. After integrating our pyrometallurgical strategies, they not only improved the purity of their essential materials but also reduced production costs through enhanced process efficiency. Their transition has led to a notable increase in their market share and sustainability initiatives.

These success stories illustrate the transformative impact of our Improved Pyrometallurgy Solutions for High-Purity Metal Production. By partnering with us, companies across various sectors have been able to distinguish themselves through exceptional material quality and innovative practices, showcasing how effective our solutions can be in achieving their manufacturing and sustainability goals.