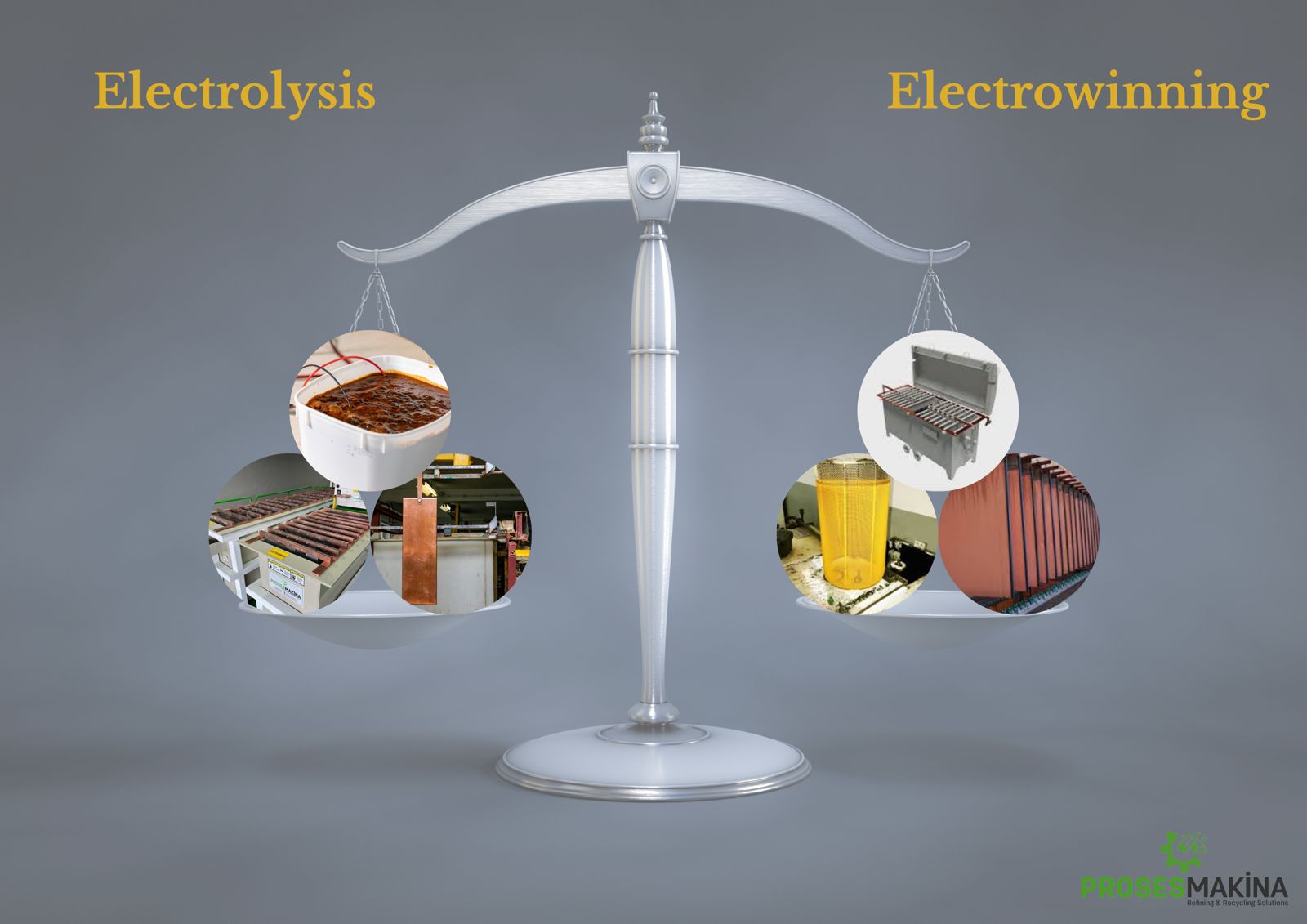

Choosing the Right Process for Metal Recovery: Electrolysis or Electrowinning

Modern industrial metallurgy relies on advanced metal recovery techniques that significantly impact the global economy. Among these techniques, electrolysis and electrowinning stand out as essential electrochemical processes. Both methods use electrical currents to extract and recover metals, but their applications and mechanisms differ. Understanding when to use electrolysis versus electrowinning is crucial for optimizing efficiency and cost-effectiveness in metal recovery operations.

Key Differences Between Electrolysis and Electrowinning

Electrolysis and electrowinning share the use of electrical currents to recover metals, yet their core principles and operational goals vary significantly.

| Aspect | Electrolysis | Electrowinning |

| Primary Purpose | Decomposing compounds, refining metals | Recovering metals from solutions |

| Anode Type | Reactive or inert | Typically inert |

| Input Material | Ionic compounds | Metal-rich solutions |

| Energy Efficiency | Higher energy consumption per kg of material | More energy-efficient per kg of metal |

- Electrolysis involves breaking down ionic compounds into their elemental forms, often for refining metals or producing chemicals.

- Electrowinning focuses on electrodepositing metals from leach solutions, making it especially suited for recovering high-value metals from industrial streams.

Applications of Electrolysis and Electrowinning

Electrolysis Applications

Electrolysis is a versatile process with applications beyond metal recovery. Key uses include:

- Metal Refining: Purification of metals like copper and aluminum.

- Chemical Production: Manufacturing hydrogen, chlorine, and sodium hydroxide.

- Compound Decomposition: Breaking down ores into base metals.

Electrowinning Applications

Electrowinning is designed specifically for recovering metals from aqueous solutions, typically following a leaching process. Common applications include:

- Mining Operations: Recovery of metals such as gold, silver, copper, zinc, and nickel.

- Metal Recycling: Extraction of valuable metals from industrial waste and spent electrolytes.

Electrowinning has become the preferred method in mining and recycling industries due to its ability to achieve metal recovery rates of up to 99%. For instance, zinc electrowinning accounts for over 90% of global zinc production.

Technical Requirements for Optimal Performance

There are minimum requirements that must be met in order for electrolysis and electrowinning systems to work. Without these conditions, it is not possible to achieve an efficient acquisition process. Some examples are mentioned below.

Electrolysis Parameters

To achieve efficient results, electrolysis systems require:

- High-purity feedstock to prevent side reactions.

- Stable temperatures around 50-70°C.

- Precise current densities to balance energy use and material yield.

Electrowinning Parameters

Electrowinning systems operate with specific requirements to ensure optimal recovery rates:

- Current Densities: Between 200-375 A/m² for metals like copper and zinc.

- Temperature Range: 40-60°C to optimize conductivity and reaction rates.

- pH Levels: 2.2-2.3 to maximize electrodeposition efficiency.

Advanced electrowinning facilities employ high-efficiency rectifiers and automated control systems to maintain these parameters. Additives like cationic surfactants can significantly reduce energy consumption, enhancing overall process efficiency.

Choosing the Right Process;

Selecting between electrolysis and electrowinning depends on several factors:

- Material Composition: Use electrowinning for metal-rich solutions and electrolysis for ionic compounds requiring decomposition.

- Energy Considerations: Electrowinning is generally more energy-efficient for recovering metals like gold, silver, and copper.

- Process Goals: Opt for electrolysis when refining metals or producing chemicals; choose electrowinning for high-purity metal recovery from industrial streams.

Both electrolysis and electrowinning are indispensable technologies in modern metallurgy, serving distinct purposes based on the material and process goals. Electrowinning excels in recovering specific metals from leach solutions with high efficiency and low energy use. Electrolysis, with its broader applications, is ideal for refining metals and decomposing compounds. Understanding the technical requirements and strengths of each method enables industries to make informed decisions, optimizing performance and sustainability in metal recovery.

Proses Makina’s Expertise

Proses Makina has achieved significant success in the design and implementation of advanced electrolysis and electrowinning systems. The company’s state-of-the-art technologies provide unparalleled recovery rates and energy efficiency, serving industries worldwide. By prioritizing environmental sustainability and leveraging years of expertise, Proses Makina continues to lead the way in metal recovery innovations, ensuring clients achieve both economic and ecological advantages in their operations.